Biomedical Engineering Reference

In-Depth Information

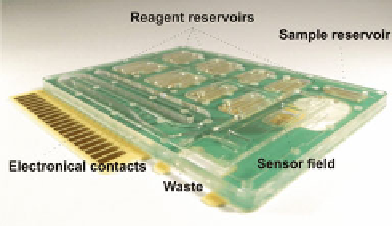

Fig. 2 Representation of the

ivD-cartridge including

functionalities

consists of two layers, a printed circuit board (PCB), and an injected-molded part,

which are assembled in production via different tapes and membranes. Never-

theless, the materials used were chosen to be cheap enabling manufacture through

serial production to gain large economies of scale.

Matching the need for a high degree of integration the cartridge was developed

to contain functionalities to perform as many steps as possible on-chip. In respect

of this, pumps, heating, reagents, as well as different sensors can be integrated into

the cartridge [

10

,

11

]. For that, the base layer is a PCB which is used to supply the

current needed for the activation of in-chip pumping or for heating. The upper

layer is an injection-molded part made from a polymer for cost-effective pro-

duction. Within this injection-molded part all necessary reservoirs for sample as

well as reagents and different microfluidic channels are integrated. Also the dif-

ferent sensors can be attached via different tapes to this part enabling their easy

assembly. Between these two layers different tapes and membranes are located.

The membrane is of particular importance for the pumping. The pumping principle

is based on the electrocatalytic generation of a gas which inflates the membrane

into the reservoirs [

10

,

11

]. With this movement the reagents or the sample are

pushed into the microfluidic channel or the sensor field where immobilized capture

molecules are located. This principle is not only be used for liquid handling. The

inflation of a membrane by means of electrocatalytic gas generation can also be

used to function as valves. This is in huge contrast to other systems that have

mostly passive components and external pumping. The pumps within the Fraun-

hofer ivD-platform have a nonlinear deflection but according to a pumping pro-

tocol constant flow rates between 0.1 and 1 lL/s can be set.

The actual design of the cartridge is chosen to provide eight reservoirs for

reagents and washing buffer and one reservoir for the sample (Fig.

2

). Four of the

eight reservoirs have a size of 150 lL, the other 75 lL, and the sample reservoir a

maximum of 45 lL to assure a small sample volume for example used when blood

from the finger tip is taken. To reduce the risk of contamination also a waste

reservoir is provided which can hold all processed liquids.

Even if the cartridge is not a prototype in the sense of materials (since the materials

used can be later applied in serial production) the size of the system is a prototype.

With eight reservoirs of the above-mentioned sizes, many different complicated

assay sequences can be performed (Fig.

3

). One example could be the washing steps

of a DNA-microarray with buffers of different stringency. Nevertheless, depending