Biomedical Engineering Reference

In-Depth Information

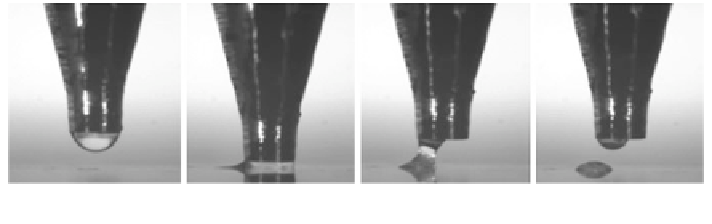

Fig. 1

Details of protein printing using stainless steel, blunt end pins

buffer onto a glass slide. From left to right the loaded pin is moving down towards

the glass surface. When the liquid at the end of the pin reaches the surface, the

protein solution gets transferred to the surface. Then the pin moves up again.

Interesting, not all of the liquid is transferred and the spot is not centred below the

pin. This unprecise locating of the spot combined with varying spotting volumes,

results in uneven spotting patterns with a great variety in spot diameters, making a

downstream array analysis unnecessarily difficult. Deposited volume shown in

Fig.

1

is between 1.5 and 2 nL

Other disadvantages include that high volumes of source solutions to be spotted

have to be provided (e.g. 96 times 30 ll, so a total of 2.88 ml spotting solution of a

single capture agent, provided to load 96 pins in parallel), which unnecessarily

increases dead volume and the manufacturing costs dramatically.

Non-contact printing potentially provides a mild printing of the capture agents

to the surface or bottom of a microplate well. Figure

2

is the graphical repre-

sentation of a non contact actuated system that shows a glass tube surrounded by a

piezoelectric element. Upon application of a signal with a typical height of 50-150

V and a duration between 10 and 50 ls the piezoelectric elements starts expanding

and compressing, thereby creating an overlay of waves inside the glass tube. On

the right side the end of such a tapered glass tube is shown. Using stroboscopic

imaging technology droplets can be visualized, clearly showing that a free flight of

droplets forms the basis for a non contact spotting technology. In the picture

shown in the right hand part a volume of exactly 300 pL is deposited.

The printing process has very low CVs and with repetition rates of up to

1000 Hz is potentially very fast which is shown in Fig.

3

. Using different com-

binations of actuation parameters in terms of pulse height and pulse length, dif-

ferent drop volumes can be generated with non contact dispensing technology

using an identical dispenser. The graph shows the dispensed volumes of 10,000

drops at different settings using a single dispenser or tip. Dispensed volumes were

determined gravimetrically and optically, where both methods resulted in CVs of

much less than 3 %.

Depending on the desired throughput in diagnostic manufacturing, samples can

be aspirated from several nanolitres to 1 ml, thereby providing a stock of liquid

that can form between 20 and 2,000,000 arrays.