Hardware Reference

In-Depth Information

x

10

x

20

x

30

x

40

(a)

L

L

0

x

1−min

x

2−min

x

3−min

x

4−min

x

1

x

2

x

3

x

4

F

(b)

L

L

d

L

max

L

0

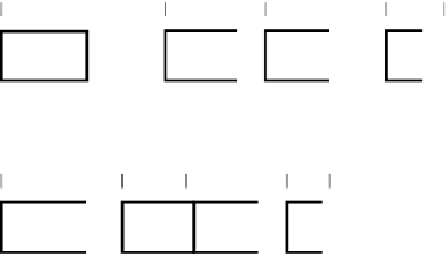

Figure 9.28

Springs with minimum length constraints (a); during compression, spring

S

2

reaches its minimum length and cannot be compressed any further (b).

=

S

i

∈

Γ

f

L

f

x

i

min

(9.36)

1

S

i

∈

Γ

v

K

v

=

.

(9.37)

1

k

i

Whenever there exists some spring for which Equation (9.34) gives

x

i

<x

i

min

, the

length of that spring has to be fixed at its minimum value, sets Γ

f

and Γ

v

must be

updated, and Equations (9.34), (9.35), (9.36) and (9.37) recomputed for the new set

Γ

v

. If there is a feasible solution, that is, if

L

d

≥

L

min

=

i

=1

x

i

min

, the iterative

process ends when each value computed by Equations (9.34) is greater than or equal

to its corresponding minimum

x

i

min

.

COMPRESSING TASKS' UTILIZATIONS

When dealing with a set of elastic tasks, Equations (9.34), (9.35), (9.36) and (9.37)

can be rewritten by substituting all length parameters with the corresponding utiliza-

tion factors, and the rigidity coefficients

k

i

and

K

v

with the corresponding elastic

coefficients

E

i

and

E

v

. Similarly, at each instant, the set Γ can be divided into two

subsets: a set Γ

f

of fixed tasks having minimum utilization, and a set Γ

v

of variable

tasks that can still be compressed. Let

U

i

0

=

C

i

/T

i

0

be the nominal utilization of task

=

i

=1

U

i

0

τ

i

,

U

0

be the sum of the

nominal utilizations of tasks in Γ

v

, and

U

f

be the total utilization factor of tasks in Γ

f

.

Then, to achieve a desired utilization

U

d

<U

0

be the nominal utilization of the task set,

U

v

0

each task has to be compressed up to

Search WWH ::

Custom Search