Agriculture Reference

In-Depth Information

hydraulic

actuator

pressure,

adjustable

spool valve

opener arm

opener

Fig. 8.6

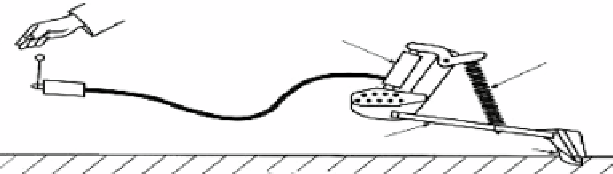

Manual pressure control for a general-purpose drill (From Scarlett

2001

, altered)

8.3.1

Control of the Seeding Depth

Commonly, the seeding depth depends either on the

pressure

that the free swinging

drill coulters exert on the soil or alternatively on the height of

spacers

such as skids

or wheels that are attached to the openers of heavier sowing units. The adjusting by

means of the pressure is used only for some bulk-metering machines. An interesting

strategy would be to adjust the depth of the coulters such that

moist soil

is attained.

8.3.1.1

Control via the Pressure Exerted on the Openers

With adjusting the

pressure

(Fig.

8.6

), the seeding depth depends on the resistance

of the soil. The higher the resistance of the soil, the lower the seeding depth is and

vice versa

. And since the resistance goes up with the speed, the seeding depth

decreases with it. Hence the travel speed should be kept rather constant. However,

controlling the pressure can also have advantages. On fields with uniform soil mois-

ture but with varying soil resistance, the openers deposit the seeds deeper in loose

soil than in more dense soil. This can be beneficial since the water transfer from the

soil to the seeds is worse in loose soil. And for getting a sufficiently recompacted soil

loose soil is helpful too - as long as the energy of the seeds suffices for emergence.

But the situation is opposite in case the moisture content varies within a field.

Because the lower the moisture content, the higher the soil resistance is (Fig.

7.3

). And

consequently, the less deep the seeds are placed. This is contrary to the respective

needs. So in summary, constant pressure can improve or impair the emergence.

8.3.1.2

Control via the Depth from the Soil Surface by Spacers

Controlling the depth of the openers from the soil surface by means of adjustable

spacers

- in most cases gauge wheels - does away with these influences. This

method is state of the art with precision drills and is increasingly used with bulk-

metering drills as well. For a precise depth control, the best location of the gauge

wheels is as close as possible to the openers and lateral of them (Karayel and

Özmerzi

2008

; Morrison and Gerik

1985

). The problem with depth control by