Geoscience Reference

In-Depth Information

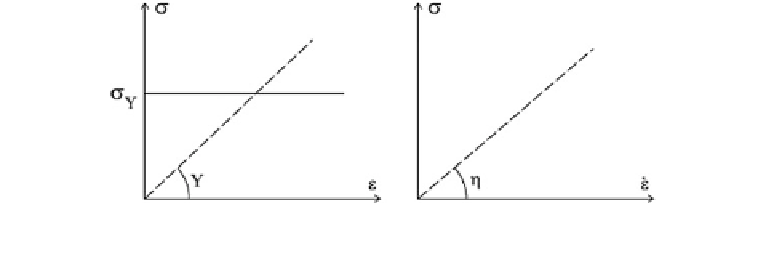

Fig. 5.4

The basic rheology models (in one dimension) for the stress

σ

as a function of the strain

ʵ

and the strain-rate

e

; E is elastic modulus,

ʷ

is viscosity, and

σ

Y

is yield strength

dimensional cases are illustrated in Fig.

5.4

. The linear elastic model assumes that stress is

proportional to strain, while in the linear viscous model stress is proportional to the strain-

rate; the proportionality coef

s

modulus) and viscosity. Rubber and water

1

are good material examples of linear elastic

and viscous media. An ideal plastic medium collapses once the stress achieves yield

strength (children

cients are, respectively, the elastic modulus (or Young

'

s modelling wax serves as an example of a plastic medium).

Mechanical analogues for these models include spring balance for linear elasticity,

dashpot

2

for linear viscosity, and static friction for plasticity.

The behaviour of a one-dimensional linear elastic beam is determined by Young

'

'

s

modulus E:

r

¼ E

e

ð

5

:

4

Þ

s modulus appears as the slope angle in Fig.

5.5

. For an isotropic three-

(or two-) dimensional case, one additional parameter is required for shear. Usually this is

treated using the Poisson

Thus Young

'

ʵ

xx

is

seen in the loading direction but contraction appears in the perpendicular directions, and

the Poisson

'

s ratio

ʼ

. For a beam in uniaxial (x) tension, tensile strain

'

is: ratio is:

e

yy

e

xx

¼

e

zz

e

xx

l

¼

ð

5

:

5

Þ

Once Young

'

s modulus and Poisson

'

s ratio are known, the bulk modulus K and the

shear modulus G are obtained as:

E

3

ð

1

2

lÞ

;

G ¼

E

2

ð

1

þ lÞ

ð

:

Þ

K ¼

5

6

Linear elastic rheology is written in three-dimensional form as

1

In laminar flow; in turbulent flow stresses are properties of the flow, not properties of the medium.

2

Such as a door stroke compressor, which dampens or softens the movements of a door.

Search WWH ::

Custom Search