Environmental Engineering Reference

In-Depth Information

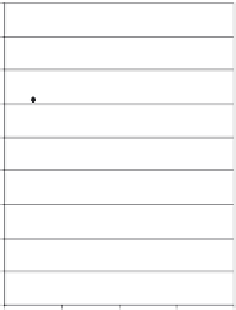

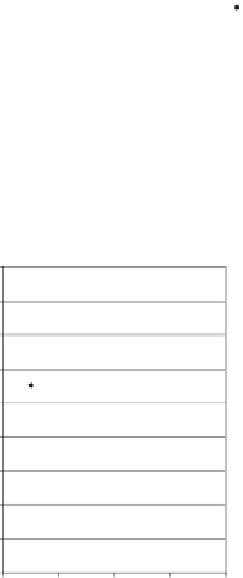

2100

1900

REFERENCE MIXTURE

100%AEV 0-8 mm

90%CEM 10%APN 0-5 mm

90%CEM 10%APE 0-6 mm

+10%APE 0-6 mm

+20%APE 0-6 mm

+30%APE 0-6 mm

90%CEM 10%THER

80%CEM 20%THER

70%CEM 30%THER

2000

1800

1900

REFERENCE MIXTURE

1700

100%AEV 0-12 mm

(A/C=1,1)

100%AEV 0-12 mm

(A/C=1,2)

100%AEV 0-8 mm

1800

1700

1600

1600

1500

90%CEM,10%APN 0-5 mm

1500

+10%APE 0-6 mm

1400

1400

1300

1300

1200

1200

FRESH

4-5 DAYS

Nº DAYS

7 DAYS

28 DAYS

FRESH

4-5 DAYS

7 DAYS

28 DAYS

Nº DAYS

Figure 1. Density tests results in the batches produced

by weight in 4 × 4 × 16 cm specimens.

Figure 3. Density tests results in the batches produced

by volume in 4 × 4 × 16 cm specimens.

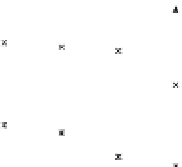

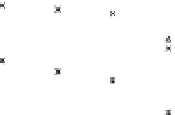

2100

2000

1900

REFERENCE MIXTURE

1900

REFERENCE MIXTURE

100%AEV 0-8 mm

90%CEM 10%APN 0-5 mm

90%CEM 10%APE 0-6 mm

+10%APE 0-6 mm

+20%APE 0-6 mm

+30%APE 0-6 mm

90%CEM 10%THER

80%CEM 20%THER

70%CEM 30%THER

100%AEV 0-12 mm

(A/C=1,1)

100%AEV 0-12 mm

(A/C=1,2)

100%AEV 0-8 mm

1800

1800

1700

1700

1600

1600

90%CEM,10%APN 0-5 mm

1500

+10%APE 0-6 mm

1500

1400

1300

1400

1200

1300

FRESH

4-5 DAYS

7 DAYS

28 DAYS

Nº DAYS

1200

FRESH

4-5 DAYS

7 DAYS

28 DAYS

Figure 2. Density tests results in the batches produced

by weight in 30 × 30 × 5 cm specimens.

Nº DAYS

Figure 4. Density tests results in the batches produced

by volume in 30 × 30 × 5 cm specimens.

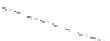

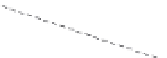

tion coefficient decreases as the density increases.

on the whole, for the 4 × 4 × 16 cm specimens

greater values were registered as compared to the

30 × 30 × 5 cm specimens.

ard Batch 100%aeV 0-12 mm has a slightly

lower absorption coefficient than the 100%aeV

0-8 mm. Therefore, it can be concluded that the

aeV 0-8 mm does not improve the capillary water

absorption coefficient.

addition of aPe 0-6 mm results in a reduction

of the absorption coefficient of up to 25% in the

+30%aPe 0-6 mm. on the other hand, the grad-

ual replacement of the cement with Thermocal

TM

results in a reduction of the absorption coefficient

of 87% for the 70%ceM 30%TheR batch.

4,00

3,00

2,00

1,00

0,00

ABSORPTION COEFF.

PARAMETERS

DENSITY 28 DAYS (kg/dm

3

)

REFERENCE MIXTURE

100%AEV 0-12 mm (A/C=1,2)

100%AEV 0-12 mm (A/C=1,1)

100%AEV 0-8 mm

90%CEM,10%APN 0-5 mm

+10%APE 0-6 mm

Figure 5. absorption coefficient ratio—Density ratio in

28 days in batches by weight (4 × 4 × 16 cm specimens).