Environmental Engineering Reference

In-Depth Information

grains and to the need of an increase of the volume

of the specimens to provide the shear failure.

The values of friction angle obtained in the

consolidated drained direct shear tests, with the

fractions passed through the 2.00 mm sieve and

through the 4.75 mm sieve are similar, while the

obtained values for the cohesion show a wide

The consolidated drained direct shear tests

results on the two entire samples led to higher

values, both in friction angles and cohesion, when

compared to previous results, which are obviously

related to the bigger dimensions of the particles

and the correspondent increase volume during the

shear failure phase.

Figure 2 shows an example of a test made with

the entire grading on the big shear box.

compaction and cBR tests were also performed,

and values for the maximum dry density were

obtained between 13.5 and 17.1 kn/m

3

, for the

optimum water content values between 4.5 and

17.7%. For the cBR the values varied between 40

and 96%.

seven in situ plate load tests were performed

with a 0.6 m diameter plate. in these tests a wide

dispersion in the values of the deformability secant

modulus was obtained, which varied between 10 and

250 MPa, for a tension of 300 kPa.

The values of the deformability modulus

obtained in situ are closer to the values obtained

in the laboratory tests, presented by serrano et al.

(2007), and are more different from the values

presented by Uriel & serrano (1976,

in

serrano

et al., 2007), which were obtained with in situ plate

load tests, using a 1 × 1 m

2

plate.

500

3.1.2

Azores samples

Tests for grain size distribution, specific weight

determination,

400

cBR

and

los

angeles

were

300

performed in laboratory on these materials.

Particle size distribution results are presented

in Figure 5, being possible to see that they are

mainly well graduated gravel. on what concerns

the particle specific weight, the values are between

19.6 and 21.6 kn/m

3

, and the water absorption

range between 3.3 and 14.8%

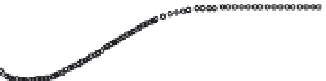

Results from los angeles on the 18 samples

tested are presented in Figure 3, showing a high

variation of values, between 25% to 70%.

according to Fraga (1988) the coefficient of los

angeles in these materials varies with the fraction

of material that is tested. That researcher found

that the same material had a value of los angeles

coefficient that was lower when tested in the finer

fractions and higher in the coarser fractions. he

also found that this variation was linearly with the

fineness modulus. The behaviour of this material

200

100

0

0

100

200

300

400

500

Normal stress (kPa)

Figure 1. Results obtained with the consolidated

drained direct shear tests on Madeira samples.

200

180

160

140

120

100

80

150 kPa

100 kPa

75 kPa

50 kPa

60

90

40

20

80

0

70

0

20

40

60

80

8

60

50

6

40

4

30

Red

Black

Red - Fraga (1988)

Black - Fraga (1988)

2

20

0

10

0

20

40

60

80

0

-2

5(D)

5,5

6(C)

6,5

7(B)

(A)

8(G)

(F) 9(E)

Horizontal displacement (mm)

Fineness modulus (Test Fraction)

Figure 2. example of a test made with the entire

grading in the big shear box.

Figure 3.

los angeles tests done in azorean samples.