Environmental Engineering Reference

In-Depth Information

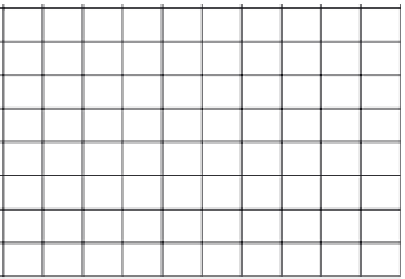

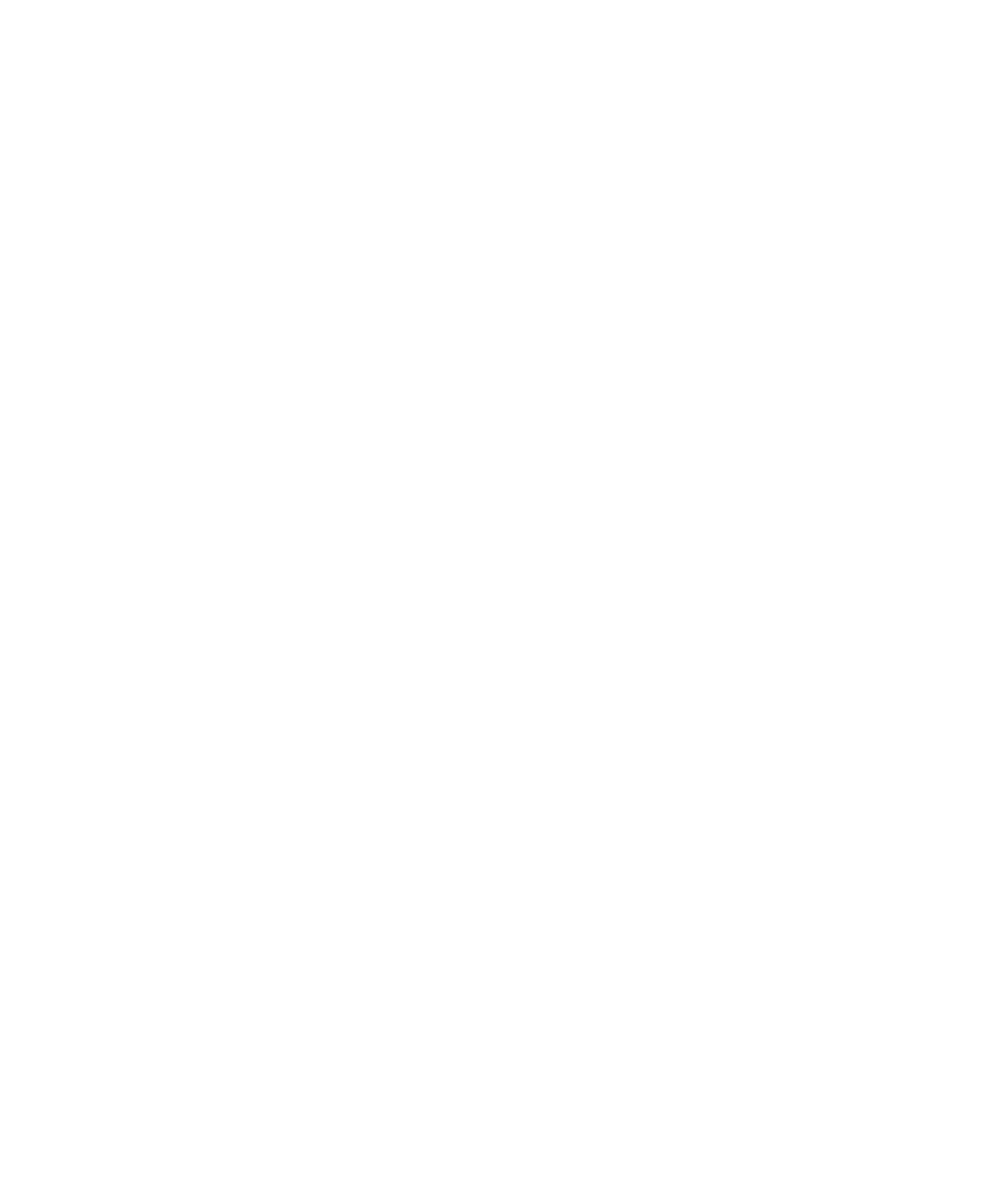

N

SPT

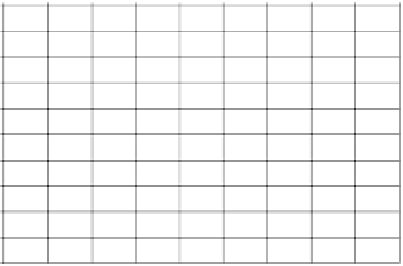

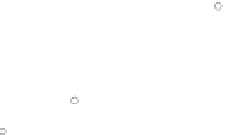

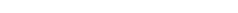

Uniaxial compression (kPa)

0510

15

20

25

30

35

40

45

0

2468 01214161820

0

0

1

2

3

4

5

6

7

8

9

10

5

10

15

20

25

30

35

40

q (kPa) = 10 + 3,35. z (m)

Average value: 5

S-A

S-B

S-C

S-D

S-A

S-B

S-C

Figure 13. Variation of uniaxial compression test

results with depth.

Figure 12.

Results of sPT tests performed in the

boreholes.

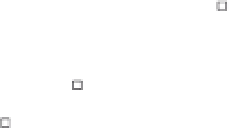

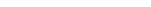

250

225

6.3

Uniaxial compression tests

seven uniaxial compression tests were performed,

whose results ranged between 19 and 41 kPa, with

an average value of 30 kPa, again indicative of

a very low resistant material. The results show a

certain increase with depth as it can be seen in

Figure 13. in two of the tests, the samples could

not be shaped due to the low consistence of the

material.

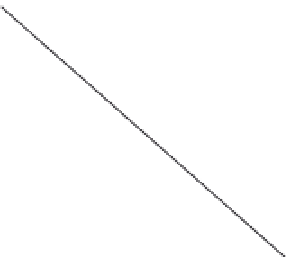

200

175

150

125

100

75

50

τ

(kPa) = 0.60 .

σ

n

+ 20

R

2

= 0.87

25

0

0

25

50

75

100 125 150 175 200 225 250

6.4

Direct shear and triaxial tests

eight direct shear tests were performed, in a

60 mm diameter circular box, with unaltered

samples taken at depths between 3 and 9 m.

Figure 14 shows the values of normal stress vs.

shear stress at failure for all the samples. The best

fitting line is also drawn.

The strength parameter values individually

deduced from the tests show cohesion between

0 and 59 kPa and friction angle between 18

and 38.5º. The values considered representative

of the strength behaviour of this material are

20 kPa of cohesion and 30º of friction angle.

Those values are typical of a silty material,

which is in accordance with the identification

values deduced from grain size distribution and

plasticity tests.

one TcU triaxial test was also performed.

cohesion of 30 kPa and friction angle of 29º

were deduced, values similar to the ones deduced

before.

Normal Strenght (kPa)

Figure 14.

Results of direct shear tests.

Table 1.

Results of pressuremeter tests.

net yield

pressure Pf*

net limit

pressure Pl*

Presuremeter

modulus

Depth

(m)

(kPa)

(kPa)

ep (kPa)

ep/Pl*

4.50

368

527

4100

7.8

10.20

525

727

3200

4.4

15.20

740

967

5700

5.9

25.20

728

907

5920

6.5

40.20

797

1097

6210

5.7

The yield net and limit net pressure values are

very low, clearly indicative of a very low resistant

material. it can be remarked a certain increase of

the values with depth due to the increase in the

confining pressure. The fact that the ratio between

limit net pressure and yield net pressure was almost

equal in all the tests (values between 1.25 and 1.43)

shows that all the tests were performed in the same

kind of material.

6.5

Pressuremeter tests

Five pressuremeter tests were performed in one

of the boreholes. The main results are collected in

Table 1.