Environmental Engineering Reference

In-Depth Information

element. nevertheless, to improve its behaviour

with regard to possible tractions or fissures which

could arise, a reinforced grating was included with

three levels of bars measuring 25 mm in diameter.

a fundamental aspect analysed in this artifi-

cial stratum is its weight since it is located over

an area which is particularly sensitive to possi-

ble overloads. With the objective of not applying

overloads any greater than those which already

existed, it was recommended to use concrete made

of light aggregate which enables achieving very

low densities and concrete with resistance of up

to 25 MPa.

it was required that the stratum be constructed

in one go to avoid any type of discontinuities which

is why it was intended for the three levels of rein-

forcing to be positioned in one go.

as a precautionary measure the area located

within the cave under the vertical of the improved

stratum had to be dismantled while work was being

performed on the surface and while waiting for the

concrete to achieve its resistance over 28 days.

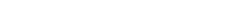

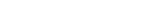

likewise, to make a more simplified analysis of

the effect of this stratum, two finite element mod-

els were made which included joining elements to

reproduce the generation of one joint throughout

the rock solid mass.

in the first calculation model the formation of

the auditorium up to its present condition is repro-

duced in successive phases. in the final phase of

the calculation a long-term hypothetical situation

is simulated in which the resistant and deforma-

tional characteristics of the vertical joints are

reduced until achieving the instability of the calcu-

lation model. The second model is exactly the same

as the first. The only difference is that in the last

phase the improved concrete stratum is added and

the bolts to verify that this reinforcement manages

to stabilise the arch of the auditorium.

be clearly seen in blocks which can be seen to have

become detached from the solid mass. nevertheless,

those which show signs of unfavourable fractures

and which have welding in their planes on the sur-

face or not must also be considered as sensitive.

5.2.1

Solutions type 2-A: Micro-seaming

of blocks

For the largest blocks of approximately 1 cubic

meter a weight was estimated of approximately

40 kn. They had to be considered as entirely sup-

ported by the treatment to be used given that ini-

tially the behaviour and orientation of the fracture

planes is uncertain, especially at depth with there

could even be the possibility of gaps appearing

(bubbles).

The treatment of these blocks was carried out

partially with the injection treatment discussed in

the previous solutions. This treatment, however,

is complemented by using the micro-seaming of

blocks and also by using fiberglass rods injected

suing epoxy resins.

For diameters which are commercially available,

the working load of the rods was calculated by using

a safety coefficient of 1.6 (maximum value which is

usually applied to conventional anchoring).

With the range of loads considered, the treat-

ment was planned with a diameter of 8 mm, with

the objective of making the hole as small as possi-

ble (approx. 2 mm in addition to the rod diameter).

in the case of the largest blocks it would therefore

be necessary to use two or three rods positioned in

such a way as to take full advantage of the capac-

ity of the rod (i.e. as parallel as possible to the

5.2

Isolated solutions: Solutions type 2

These are solutions which aim to secure blocks

from 10 centimeters up to 1 m

3

which could become

detached from the rock solid mass being in a strict

equilibrium situation. This strict equilibrium can