Environmental Engineering Reference

In-Depth Information

1

2

3

4

5

6

7

8

9

10

11

12

0

-2

-4

-6

-8

1m - Exc.

2m - Exc.

1m - Emb.

2m - Emb.

-10

-12

-14

0

38

76

114

152

190

228

266

304

342

380

418

Total Excavation (m)

0

2

4

6

8

10

12

Axial Force (ton.)

Obs. A0

Obs. B0

Obs. C0

3D-A0

3D-B0

3D-C0

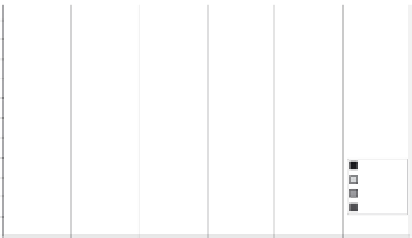

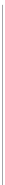

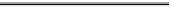

Figure 18.

axial force diagram for the rockbolts.

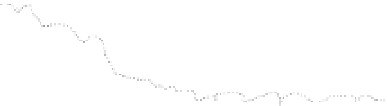

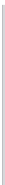

Figure 20. evolution of vertical displacements (exten-

someter 0—profile P4) with time.

Distance to the Axis of the Cavern (m)

-50

-40

-30

-20

-10

0

10

20

30

40

50

0

-1

0

-2

-2

-3

-4

-6

-4

-8

-5

Observed

3D Calculation

-10

0

38

76

114

152

190

228

266

304

342

380

418

-6

Total Excavation (m)

Obs. A2

Obs. B2

Obs. C2

3D-A2

3D-B2

3D-C2

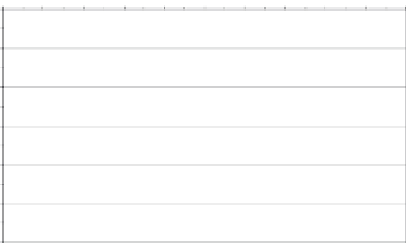

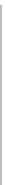

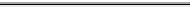

Figure 19.

surface settlement profile—Profile P2.

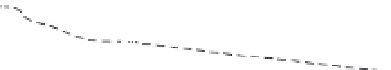

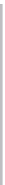

Figure 21. evolution of the vertical displacements

(extensometer 2—profile P4) with time.

in Figure 18 the result of one of these studies is

shown for the two models. it can be concluded that

if the rockbolt's spacing is changed from 1 to 2 m,

the axial force becomes larger, but still far from the

mobilized forces are equivalent in both models,

mainly in the upper levels. in the lower levels, the

excavation model originates larger values.

From the economical and structural point of

view, this parametric study allowed to achieve an

optimal solution for the bolt mesh.

those that have been observed (the latter ones are

only a bit larger).

Figures 20 and 21 shows the evolution of the verti-

cal displacements for two distinct points of profile P4.

at the axis (extensometer 0), the vertical displace-

ments predicted by the calculation are smaller than

the observed values. in extensometer 2, points B and

c, the opposite occurs and the calculated displace-

ments are larger. The biggest difference is found in

point a, located at the surface, where the measured

displacement was very large, especially when com-

pared with the points at greater depths.

Finally, in Figure 22, the horizontal displace-

ments recorded by the inclinometers located at

profile P4 are compared with the results of the 3D

numerical modelling.

in Figure 22, the transverse horizontal displace-

ment (x direction) are shown and good agreement

between the calculations and the measured values

can be seen, especially in the excavation zone where

a maximum displacement of 6,0 mm was obtained,

against the 5,5 mm predicted by the numerical

modelling.

The horizontal displacements in the longitu-

dinal direction returned by the calculations were

very small and in Figure 22 it is shown that they

5

coMPaRison BeTWeen The

PReDicTeD anD oBseRVeD ResUlTs

as shown in the previous sections, no relevant

differences between the two models were found

and so the comparisons will only regard the

observation data and the results given by the

embankment model.

Figures 19 to 21show both the vertical displace-

ments yielded by the 3D calculation and the obser-

vation data from two profiles (P2 and P4).

The first figure has the results for profile P2.

it can be concluded that the final displacements

estimated by the numerical analysis agree well with