Environmental Engineering Reference

In-Depth Information

water ph values (5,5 to 6,5), according to water

physicochemical analysis. The pumping station

final lining comprises reinforced concrete walls

(e = 0,50 m), topped by a semi-circular vault

(e = 0,50 m) with an inner section of 5,50 m radius.

The total height is about 26 m, having a strut in the

middle, materialized by the ground floor slab.

2.5

Instrumentation and observation

considering the specific aspects of the project,

the geotechnical and geological conditions of the

site, and the spatial configuration of the cavern, an

instrumentation plan was defined in order to allow:

i) evaluation of safety during construction works;

ii) comparison between the design assumptions

and the observed behaviour; iii) extrapolation of

the behaviour from the early stages of excavation

to the later ones, in order to modify and adapt, if

necessary, the construction methodology and the

structural solutions according to the observed dis-

placements of the rock mass.

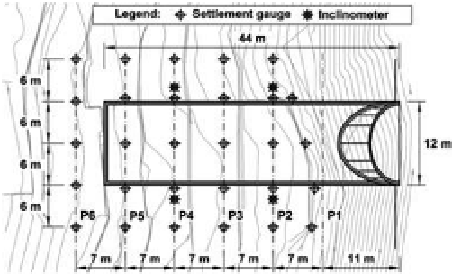

in order to achieve this purpose, six instrumen-

tation profiles were defined, with a distance of

7 m between them, which allowed measuring the

following quantities: i) superficial settlements—24

settlement gauges; ii) sub-surface vertical move-

ments—six extensometer rods with two reading

points each; iii) lateral movements—four inclinom-

eters; iv) and convergences—through the use of

several survey points. The location of these instru-

ments is shown in Figures 8 and 9.

Figure 8.

Plan of monitoring profiles.

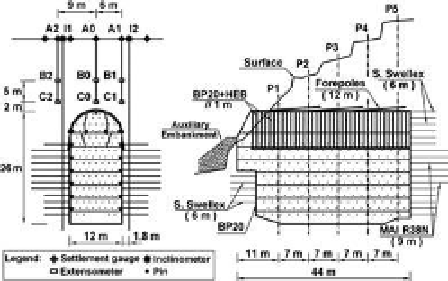

Figure 9. Geometry and instrumentation profiles: a)

cross section; b) longitudinal profile.

3

PRoJecT chaRacTeRisTics

oF WaTeR sToRaGe anD aUXiliaRY

TUnnels

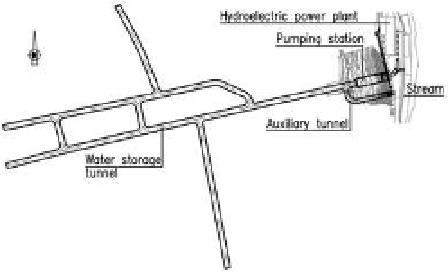

Water storage tunnel has 1250 m length, and a

transversal section of 7 m × 5 m, in order to store

40,000 m

3

of water. The longitudinal inclination is

0,01%.

The tunnel alignment was defined during the

execution phase, searching the formations with

the best geological and geotechnical characteristics

in terms of stability and water-tightness, reducing

also the associated costs; therefore several branches

were executed, easing the vehicles circulation inside

and allowing the creation of several work fronts

The auxiliary tunnel function is to give access

to the water storage tunnel and to the pumping

station, in order to execute maintenance and

inspection works, being also used as an access dur-

ing the construction phase. This tunnel has 73 m

long and a cross-section of 5,5 m × 5,5 m, being

horizontal in the initial 10 m, having then a 13,5%

inclination up to the water storage tunnel.

Figure 10.

Water storage tunnel alignment.

The primary support was defined in the entire

perimeter, working also as a final lining—in Table 2

the adopted solutions are defined, presenting in

Figure 11 the ZG2 geotechnical zone correspond-

ing sections. concerning the execution phasing,

the ZG1 zone was excavated in full face (in the

areas with worst characteristics advances were

made from 10 to 10 m in the higher half-section),

while in the ZG2 and ZG3 zones the excavation

was executed first in the higher half-section and

only afterwards in the lower half-section—in these