Environmental Engineering Reference

In-Depth Information

they are translated to forces in every joining

material of the macroporous.

5. every contact is checked one by one in order to

break those that have exceeded the maximum

allowable force by the failure diagrams, (n, Q, pair

of values that produces the reach of the Tresca

criterion in the tablet joining material) obtained in

the FeM calculus. The contacts that had broken

are removed from the macroporous by deleting its

contribution to the stiffness matrix [F].

By increasing the load progressively further

displacements and inner forces are calculated to

check how many contacts had broken. in addition,

the position (dip and dip direction) of the broken

contacts are measured.

This process is repeated until the macroporous

cannot reach the equilibrium with the external

load. When this situation happens it is said that

the collapsed of the macroporous material had

taken place.

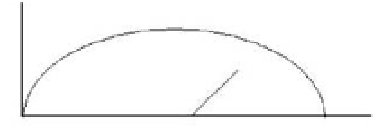

q

collapse surface

B

p

A

Figure 7. example of the trajectory of tensions during

a collapse calculi.

4

FiRsT ResUlTs

The model is actually in an early stage of

development and needs some improvements. But

the first results obtained with this methodology

are promising. For example, without having

reached the collapse, we have been able to observe

the following:

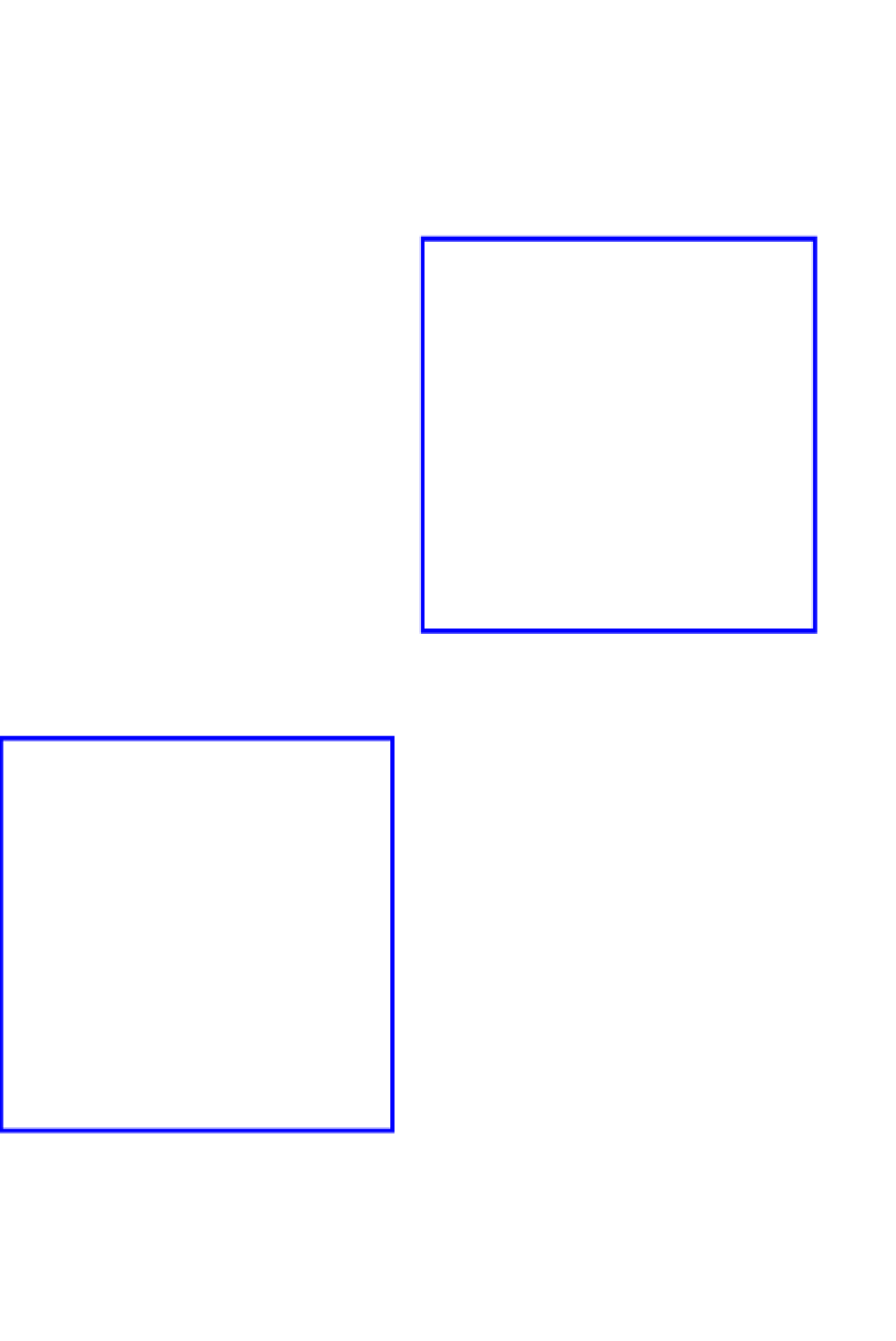

1. in the early steps of loading (point a in

Figure 7

), the first contacts to break had been

the ones with a low dip angle independently

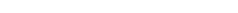

Figure 8. contour plot of concentration of poles that

has broken on the advanced steps of loading.

of the dip direction. That is to say, the more

vertical contacts are the firsts to break as can be

seen in Figure 6.

2. But when the load is progressively increased

(deviatoric), from point a to point B, as can be

seen in Figure 7, new contacts broke. These new

ones are not horizontal but near to 45º of dip

angle instead. This can be seen in Figure 8.

it is thought that in more advanced steps of

loading; the concentration of poles among 45º

of dip angle will generalize in every dip direction,

leading to the collapsed of the macroporous.

5

conclUsions

in this research, the first steps on how to model

the collapse of a macroporous material had been

shown. The model is in an early stage of develop-

ment and this article is only trying to enounce one of

the possible ways to model this kind of fragile break.

Figure 6. contour plot of concentration of poles that

has broken on the early steps of loading.