Environmental Engineering Reference

In-Depth Information

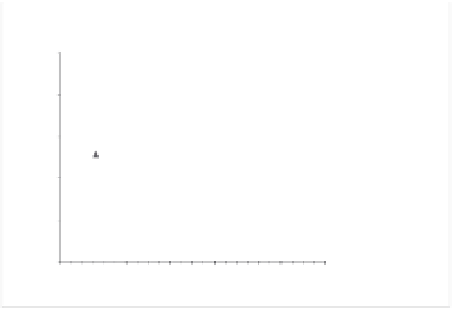

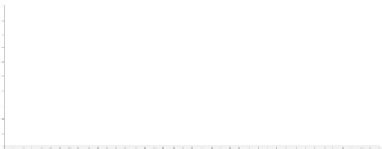

Modified Proctor compaction curves for basaltic aggregates

from Azores, Cape Verde and Canary Islands in comparison

with non-volcanic materials

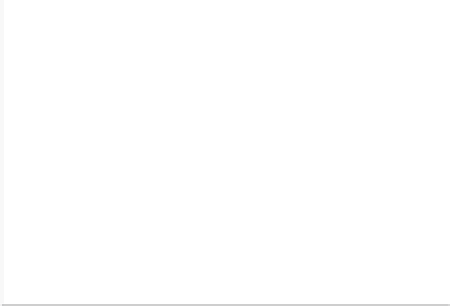

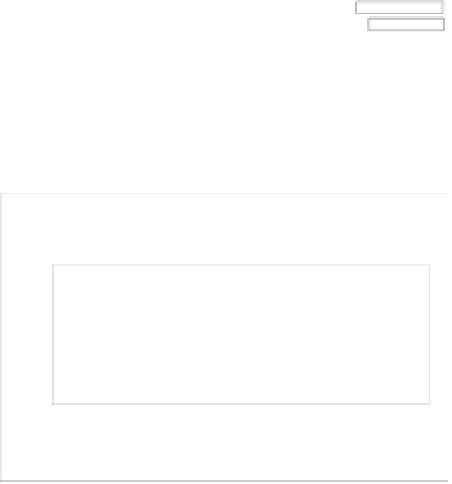

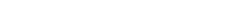

Experimental test section: CGA on existing aged asphalt

pavement.

20 kN applied load

24,00

Azores Basalt (1)

Azores Basalt (2)

Azores Basalt (3)

Granite

Limestone

Gneiss

Cape Ve rde Basalt (1)

Cape Ve rde Basalt (2)

Cape Ve rde Basalt (3)

Cape Ve rde Basalt (4)

Gran Canaria Basalt (ZA-25) (1)

Gran Canaria Basalt (ZA-25) (2)

Gran Canaria Basalt (ZA-40) (3)

100

90

23,00

80

85th Pe rcentile = 75

70

Mean value = 66

60

22,00

50

40

30

21,00

20

10

0

20,00

19,00

Station

2345678910

11

12

13

14

Moisture content (%)

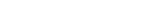

Experimental test section: CGA on new subgrade of lapilli.

20 kN applied load

Figure 6. Modified Proctor compaction curves for

some volcanic granular aggregates from different origins,

compared with non-volcanic materials.

180

160

140

85th Pe rcentile = 124

120

Me an value = 114

100

layer below multiplied by 1.3. likewise, the rate

k = e

V2

/ e

V1

(e

V1

= modulus measured in the first

cycle of load) is restricted to be lower than 2.2.

experience with volcanic materials from canary

islands indicates that, in general, ordinary control

criteria applied to granular soils and aggregates can

be also implemented to volcanic unbound materi-

als. however, the standard requirement related to

the allowable limit of the coefficient k = 2.2 results

achievable with some difficult according to previ-

ous experience, even with the lift rightly compacted.

This can be explained by the lack of fine-size par-

ticles in crushed volcanic aggregates. Thus we sug-

gest a less restrictive value of k = 2.5 with excellent

structural performance of granular layers.

80

60

40

20

0

Station

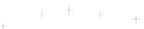

Figure 7. effective Moduli of the cGa base course

foundation, backcalculated from FWD tests (20 kn

applied load). [Values marked with (*) have been

excluded from percentile calculations for being unusually

extreme].

3.3

Characterization of the granular course

foundation

assuming that all significant factors affecting com-

paction (granular material characteristics and origin,

moister content, lift thickness, compaction equipment

type and compaction energy) have been unchanged

in both in-situ trial road sections, and only the base

course foundation conditions have varied, the differ-

ences between rates of compaction observed suggest

that this latter factor has determined the compac-

tion process. hence, FWD tests have been carried

out with the purpose of characterizing the support-

ing subgrades and to directly evaluate their dynamic

response.

in Figures 7 and 8, the measured effective Mod-

uli (for 20 and 40 kn of applied load) of the caG

base course foundation are illustrated, comparing

both trial road sections. The effective Modulus is

a measure of the effective or combined resilient

stiffness (i.e. ratio of the applied cyclic stress to the

recoverable or elastic strain after many cycles of

repeated loading) of all layers below the tested sur-

face, backcalculated from FWD defections.

The resulting values show that Moduli of the

caG base course foundation are notably different

in both situations. stiffness obtained on existing

3.2.2

Control methodology in Iceland

in accordance with the icelandic Building Research

institute (iBRi), the field compaction control is

founded on attaining a minimum value of 98% of

Modified Proctor maximum dry density for base

courses and 95% for subbases. it is also habitual to

specify the k-coefficient to be lower than 2.5 for

the heaviest traffic, what provides support and is

consistent with our experience with canary mate-

rials and suggested value of k.

3.2.3

Control methodology in Hawaii

standard specifications for aggregate road base

courses of hawaii Department of Transportation

(hDT 2005) based on relative density and moisture

content are also end-product specifications. article

304.03 “aggregate base course. construction” states

to achieve al least 95% of relative compaction (based

on Modified Proctor maximum dry unit weight)

and to obtain water content within 2% above or

below optimum. it should be noted that maximum

compacted thickness of one lift shall be 6” (15 cm)

according to this standard.