Environmental Engineering Reference

In-Depth Information

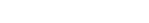

Table 1.

laboratory test results of cGa samples obtained from stockpile and from trial road sections.

compacted on

existing pavement

compacted on

subgrade of lapilli

From stock-piling

Flakiness index (%)

23

19

19

elongation index (%)

29

25

20

specific

# >20 mm

-

26.19

26.29

gravity of

# 4/20 mm

-

26.49

26.59

solids

# <4 mm

-

27.08

27.08

(kn/m

3

)

Mean

-

26.78

26.78

Water

# >20 mm

-

2.1

2.0

absorption

# 4/20 mm

-

1.9

1.8

(%)

# <4 mm

-

1.2

1.8

Mean

-

1.6

1.8

Modified

-

22.76

22.76

γ

d

(max.)

Proctor

(kn/m

3

)

laboratory

-

7.5

7.5

ω

optim.

(%)

test

γ

d (max.)-c

*

-

23.05

23.05

(kn/m

3

)

ω

optim.-c

* (%)

-

7.0

7.0

* Maximum dry unit weight and optimum moisture content with coarse-particle correction, according to asTM

D-4718-87.

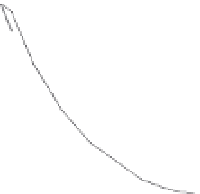

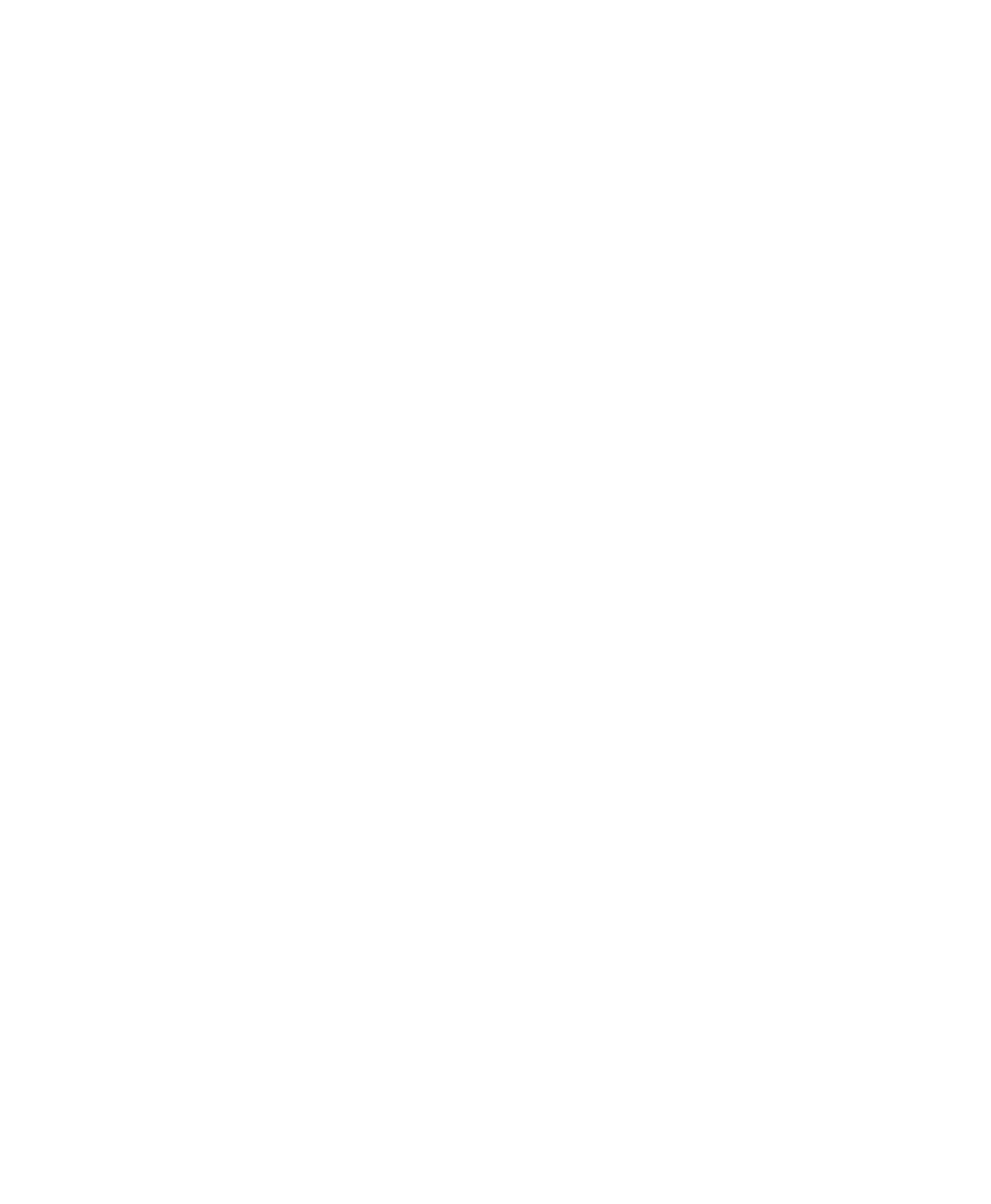

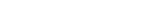

Grading curves and comparison with Portuguese and Spanish

specifications

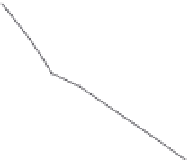

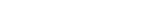

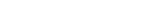

Grading curves compared with EN 13285 specifications and

tolerance limits

100,00

100,00

Me an grading curve (CGA on existing pave ment)

Me an grading curve (CGA on lapilli s ubgrade)

Stockpiling grading curve

Upper limit EN 13285

Lower limit EN 13285

Upper limit EN 13285 (Declared curve)

Lower limit EN 13285 (Declared curve)

Me an grading curve (CGA on existing pave ment)

Me an grading curve (CGA on lapilli subgrade)

Stockpiling grading curve

Upper limit (EPE, 0/31.5)

Lower limit (EPE, 0/31.5)

Upper limit (PG-3, ZA25)

Lower limit (PG-3, ZA25)

90,00

90,00

80,00

80,00

70,00

70,00

60,00

60,00

50,00

50,00

40,00

40,00

30,00

30,00

20,00

20,00

10,00

10,00

0,00

0,00

100,00

10,00

1,00

0,10

0,01

100,00

10,00

1,00

0,10

0,01

Particle size (mm)

Particle size (mm)

Figure 3. Particle-size distribution curves of cGa sam-

ples and Portuguese and spanish grading envelopes of

road specifications.

Figure 4. Particle-size distribution curves of cGa

samples and allowable tolerance (with respect to manu-

facturer declared grading curve) and grading envelope

specified in en 13285.

erties, owing to their heterogeneous nature) caused

by raw material alterations, aggregate manufacturing

process (crushing, grinding and sieving), and stock-

piling manipulation conditions (Franesqui 2009).

Table 1 summarizes laboratory test results. The

mechanically-crushed local material has resulted

slightly lacking in particle size over 9.5 mm,

according to 0/31.5 grading envelope of Portuguese

specifications (ePe-98), and over 2 mm in accord-

ance with spanish standard PG-3 for Za25. how-

ever, the Uniformity coefficient and coefficient

of curvature (cu = 62; cc = 1.9-2.0) indicate an

easily compactable material. in the same way, ana-

lysed cGa samples are acceptably adjusted to

0/20 gradation according to French specifications

(nF P-98-129).

Particle-size distributions have revealed a grading

modification caused by field compaction with respect

to stockpiling material, although not clearly signifi-

cant (fine aggregate fraction increased by 1.5% and

improvement of coarse aggregate particle shape).

The european standard en 13285 related to

unbound mixtures states requirements regarding

regularity of grading properties, and defines the

tolerance limits with respect to the manufacturer

declared grading curve. Figure 4 illustrates, similarly,

that tested cGa samples were found to satisfy these

allowable tolerances and the grading envelope estab-

lished in the aforementioned standard for the most

severe categories (oc

90

and G

a

), confirming a good

quality manufacturing and stockpiling control.