Environmental Engineering Reference

In-Depth Information

4.3

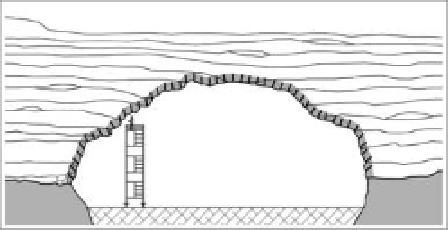

Short bolts

it was intended to create a consolidated arch of

approximately one meter thick. in order to achieve

this arch, meter long and 22 mm diameter bore-

holes were drilled. Fiberglass and polyester bolts,

with high resistance to traction and inert to saline

aggression, were introduced in the boreholes. The

structural characteristics of the bolts are: deforma-

tion module 47 GPa, resistance to traction 1040 MPa

and maximum elongation 2.3%. The approximate

grid was 1 × 1 meter. once each bolt was intro-

duced the borehole was sealed and a medium vis-

cosity epoxy resin (30,000 cP) was injected to form

a consolidated stone block.

since it was impossible to find in the market

suitable drilling machinery for these works, very

light and powerful pneumatic drilling machinery

were designed. a total of 2000 short bolts were

specially manufactured for this job.

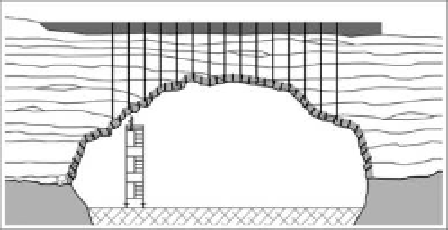

Figure 5.

consolidation of the 4 meters thick arch.

4.4

Long bolts

once this monolithic rock layer was achieved it was

necessary to tie this first meter to the higher strata,

and somehow “hang” that first consolidated meter

from higher strata. To do so, 46 mm diameter bore-

holes were drilled, at least 4 m long. The grid was

2 × 2 m. it was planned to place in each of these

holes a long bolt, fiberglass and polyester made,

four meters long and 25 mm diameter, that later,

as in the case of short bolts should be injected with

medium viscosity epoxy resin. Before this step an

inspection of the boreholes was carried out with a

TV camera, founding out that there were numer-

ous large hollows. This forced to unplanned sup-

plementary treatment, described below.

once the boreholes were drilled they were

injected with expansive polyurethane resins, able

to increase up to 20 times its original volume with-

out applying pressure when swelling. By doing so,

the hollows were filled allowing drilling the bore-

holes again, placing the fiberglass bolts and their

subsequent injection with epoxy resins. More than

5000 liters of these resins were consumed.

Figure 6.

lightweight concrete slab.

4.5

Lightweight concrete slab

in specific areas, higher strata, above the first meter

consolidated arch, were considered insufficient to

carry the long bolting. For this reason, an artificial

stratum was created to anchor the long bolts, using

a lightweight reinforced concrete slab.

once lightened concrete had hardened, a grid

of boreholes of 46 mm diameter was drilled from

the concrete slab. The TV camera was introduced

in every borehole, discovering numerous large

hollows that decreased dangerously the remain-

der structural resistance to the entire area. it was

decided to fill these gaps by injecting a grout of

low-density, high strength, excellent adhesion to

the rock and null retraction.

after that the boreholes were redrilled introduc-

ing a 25 mm fiberglass and polyester bolt in each

of them, diameter, which was injected with resin

epoxy resin.

4.6

Micro bolts

in specific areas, with the aim of holding loose

rocks, small reinforcements of micro bolts of

8 mm diameter and variable length up to 50 cm

long, and capable of supporting up to 160 kg

were made with from fiberglass resin polyester.

The annular space between rock and bolts was

also injected with resin epoxy. a total amount of

1200 items were made.

Figure 4.

consolidation of the one meter thick arch.