Environmental Engineering Reference

In-Depth Information

400

NB-4 (23.6-23.8m) (compacted state)

soaking at constant vert. stress

initial water content: 32%

NB-4 (23.6-23.8m) (compacted state)

0.0

300

200

0.5

100

1.0

0

0

100

200

300

400

Vertical effective stress,

σ

'

v

(kPa)

1.5

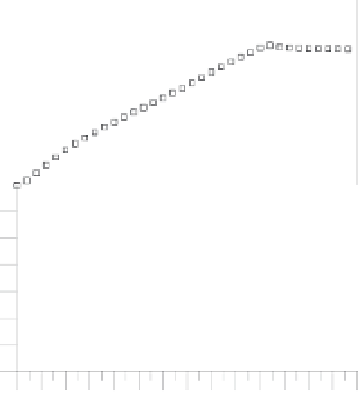

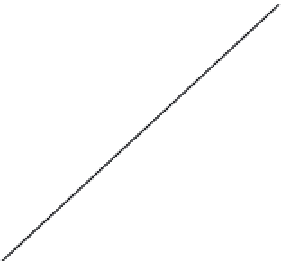

Figure 15. shear strength envelope for ultimate condi-

tions. compacted sample nB-4. shear strength parameters.

0

100

200

300

400

Vertical stress (kPa)

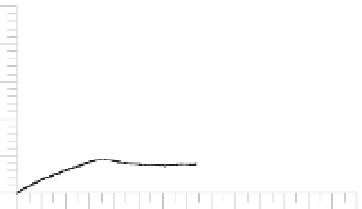

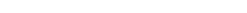

Figure 13. evolution of vertical strain (collapse) dur-

ing soaking at different vertical stresses. compacted

sample nB-4.

500

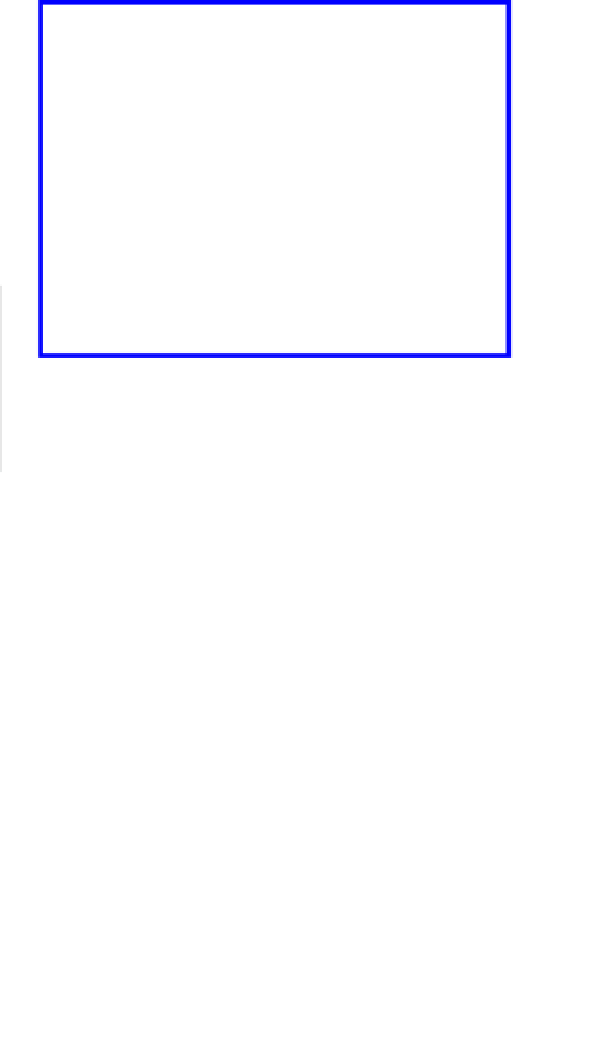

NB-4 (23.6-23.8m) (compacted state)

σ

'

v

= 52kPa

400

σ

'

v

= 104kPa

σ

'

v

= 208kPa

300

σ

'

v

= 364kPa

200

100

0

-0.4

-0.2

0

0.2

0.4

0.6

0.8

Figure 16. compacted tuff sample. saturated sample

after pinhole test. The 1 mm hole did not erode.

practice is dependent on the amount of “damage”

or remoulding induced by excavation and compac-

tion procedure.

02468 0 21

Horizontal displacement (mm)

4

Figure 14. evolution of shear stresses and vertical

displacements during direct shear test on compacted

sample nB-4.

2.7

Hydraulic-related behaviour

a water permeability test was also run on com-

pacted sample nB-4 using controlled-gradient

conditions in an oedometer cell under loaded

conditions (50 mm diameter and 20 mm high

specimen). The vertical total stress applied was 75

kPa. Water pressure of 30 kPa was applied at the

bottom of the sample. Pressure at the top of the

sample was maintained under atmospheric condi-

tions. a saturated permeability of

k

= 3.5 × 10

-10

m/s under steady state conditions was measured.

compression stress). Figure 15 shows the shear

strength envelopes for ultimate conditions, and the

shear strength parameters.

compacted tuff exhibits a high drained fric-

tion angle (43°) and a ductile behaviour. however,

when remoulded and tested for residual condi-

tions the friction reduced to 29°. The question of

the appropriate strength parameters to be used in