Environmental Engineering Reference

In-Depth Information

NB-4 (23.6-23.8m) (natural state)

peak stress

just after peak

ultimate conditions

1.40

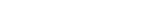

NB-4 (23.6-23.8m)

Standard Proctor

400

1.30

350

300

S

r

=1

250

1.20

200

S

r

=0.8

150

1.10

100

8 2 6 0 4 8 2 6 04

Water content,

w

(%)

4

50

Figure 12.

standard effort compaction curve (nB-4).

0

network formed by large inter-aggregate pores

between aggregations or grains of approximately

3-8 µm, and smaller intra-aggregate pores inside

aggregates or grains between 20-50 nm. although

the compaction at standard effort allowed easily

reaching dry densities similar to the natural con-

dition, it is important to remark that this density

was achieved with dominant macro-pore sizes and

macro-porosity larger than those found for the

fact, a slightly larger water permeability and com-

pressibility on loading and soaking (collapsibility)

of the compacted material compared to the intact

one is expected.

0

50

100

150

200

250

Vertical effective stress,

σ

'

v

(kPa)

Figure 11. shear strength envelopes for different con-

ditions (peak, just after peak and ultimate conditions).

intact core sample nB-4. shear strength parameters.

oedometer cell under loaded conditions (50 mm

diameter and 20 mm high specimen). The vertical

total stress applied was 75 kPa. a water pressure

of 30 kPa was applied at the bottom of the sample

by a GDs instruments advanced pressure/volume

controller with a pressure resolution of 1 kPa and

a volume resolution of 0.5 mm

3

/step. Pressure at

the top of the sample is maintained under atmos-

pheric conditions. The saturated water permeabil-

ity is determined under steady-state conditions.

saturated permeability is low (3.5 × 10

-10

m/s)

(in just one determination). This is a value repre-

sentative of “matrix” conditions. in the absence of

fractures/joints tuff permeability is low. This low

value is significantly lower than some field deter-

minations in boreholes.

The pin-hole test performed identified a non-

dispersive material (nD-1).

2.6

Wetting under load behaviour

and strength tests

These tests were carried out in a direct shear cell.

The same steps were applied as for the intact speci-

mens: a) loading at constant (initial) water content;

b) soaking at approximately 1 min (this saturation

stage was maintained for 24 hours); and c) shearing

during 1 day at constant horizontal displacement

rate of approximately 5 µm/min up to a maximum

of 8 to 9 mm. The vertical stresses applied were 52,

104, 208 and 364 kPa. During soaking at constant

vertical stress, the compacted sample underwent

some compression (collapse), which increased with

vertical stress, as shown in Figure 13. The larger

compressibility on loading and soaking (collapse)

is consistent with the larger macro-pore sizes

and macro-porosity found by mercury intrusion

porosimetry on the compacted material.

The evolution of shear stresses and vertical dis-

placements at different vertical effective stresses

during direct shear tests is presented in Figure 14.

The specimen is now essentially ductile. Dilatancy

is recorded for the low stress range (<100 kPa of

2.5

Compaction

core samples were crushed and dynamically com-

pacted in one lift using standard effort: 600 kJ/m

3

.

Maximum dry density is 1.26 Mg/m

3

(void ratio of

0.920) at water content between 32 and 37% and

degree of saturation between 84 and 97% (refer to

The pore-size distribution curve of the com-

pacted material nB-4 obtained by mercury intru-

sion porosimetry is also presented in Figure 8

together with the intact material for comparison.

The compaction process led also to a double-porosity