Environmental Engineering Reference

In-Depth Information

200

100

SG

Shear zone Test 2

Shear zone Test 3

Shear zone Test 5

Shear zone Test 6

Inner shear zone Test 6

Outer shear zone Test 6

S20

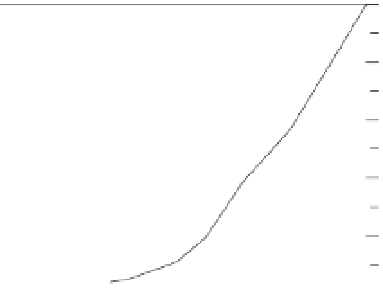

Total stress path

Effective stress path

Stop

80

150

A

60

100

C

40

50

20

B

Start

ϕ = 39°

0

0

0.01

0.1

1

10

0

50

100

150

200

250

Grain size (mm)

Normal stress (kPa)

Figure 11. Grain size distributions determined on the

original material (sG) and on the material forming the

shear zones of specimens from different tests.

Figure 9.

effective and total stress paths during test #5.

0.80

0.75

of 20 m, experienced severe crushing. its grain

size distribution is very similar to that determined

by Boldini

et al

. (2009), denoted as s20, in stress-

controlled ring shear tests carried out to values of

shear displacement larger than 30 m.

Finally, the grain size distribution of the shear

zone in test #5, despite the limited shear displace-

ments reached at the end of the experiment, indi-

cates that a significant crushing occurred, which

helps in explaining the limited liquefaction phe-

nomenon observed soon after the increase in shear

displacement.

0.70

0.65

0.60

0.55

0.50

0

0.2

0.40.6

0.811.21.4

1.6

Shear displacement (m)

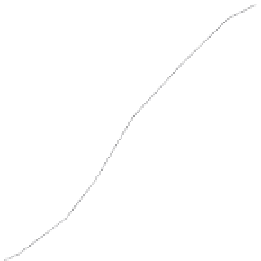

Figure 10.

Void ratio decrease recorded during test #5.

5

conclUsiVe ReMaRks

build-up of pore water pressure as a consequence

of intense grain crushing in the shear zone. evi-

dence of this is the significant decrease in void

ratio recorded during the test (

Fig. 10

). The final

void ratio determined for the shear zone is equal

reported in section 4.1 disregarding swelling of the

specimen (about 2 mm), following the opening of

the apparatus.

The new lRsT testing programme confirmed pre-

vious results and gave new insight into the texture

modification experienced by the volcaniclastic

material during shearing.

The high susceptibility of the stromboli vol-

caniclastic soil to static liquefaction, observed in

previous and new tests conducted under stress-

controlled undrained conditions, was confirmed

by displacement-controlled tests performed with

open drainages. even though a threshold for the

insurgence of static liquefaction was neither estab-

lished, nor could be easily extended to the real

slope, a specimen tested at high displacement rate

(100 mm/s) temporarily experienced shear failure,

whilst specimens sheared at 5 mm/s did not exhibit

any significant drop in shear resistance. This

behaviour could be assimilated to the limited liq-

uefaction described by castro (1969) in undrained

triaxial tests. alternatively, since drainages are

open, the strength recovery could be simply due to

the dissipation of the excess pore pressure.

4.3

Grain size distribution after shearing

The grain size distribution of the shear zone mate-

rial was determined for different tests (

Fig. 11

).

The grain size distribution of the inner and outer

shear zone of test #6 specimen is also provided.

Figure 11 shows that the material from the shear

zone of tests #2 was subjected to a very limited

crushing and the corresponding curves almost

match that of the original material sG.

conversely, the material forming the inner shear

zone of test #6, subjected to a shear displacement