Environmental Engineering Reference

In-Depth Information

static liquefaction (Boldini

et al

. 2009). Further

tests, presented in this paper, were conducted

at DPRi of kyoto University using different

drainage and shearing conditions, measuring

void ratio and grain size changes. The aim is to

link shear failure to the evolution of state param-

eters and soil texture within the shear zones, in the

perspective of defining mode of slope evolution

leading to failure.

of scoriaceous lava (autoclastic breccia) having the

same porosity of the grains (Rotonda

et al

. 2010).

This material, taken at the lava flow fronts, repre-

sents a major source for the productions of volcani-

clastic grains. The uniaxial compressive strength

and the tensile strength from Brazil tests, deter-

mined on cylindrical specimens 42 mm in diameter,

are characterised by a mean value of 34.5 MPa and

4.01 MPa respectively which account for crushing at

moderate stresses.

2

The MaTeRial

3

PReVioUs TesTs

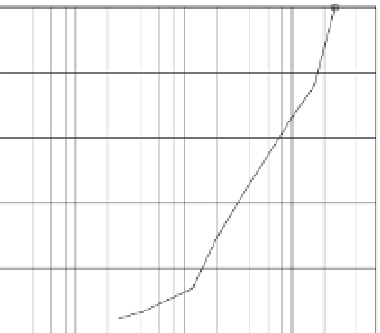

The material used in all tests comes from layers

of sandy gravels (curve a in

Fig. 1

) sampled from

horizons of the volcaniclastic sequence outcrop-

ping at the foot of the sciara slope. To ensure a con-

venient ratio between the maximum grain size and

the minimum specimen dimension, tests were per-

formed on the fractions passing the 8 mm sieve.

Therefore the in situ grain size distribution curve

was shifted parallel to the grain size axis obtain-

ing a reference soil (curve sG in

Fig. 1

) classified

as sand and gravel, with uniformity coefficient of

9.6. in situ void ratio, calculated from the in-situ

density of a volcaniclastic layer with a particle size

distribution similar to that of the material used in

laboratory tests, is 0.83.

Grains are mostly basaltic scoriae and scoria

fragments with high roughness and low sphericity.

average porosity, created by widespread pores often

tortuous, is 17.5%. Previous tests (Tommasi

et al

.

2005) indicate that grains exhibit relevant crushing

occurring as collapse and rupture of surface asperi-

ties. This behaviour induced to evaluate the strength

of the grains, which was investigated through stand-

ard tests on cylindrical specimens cored from blocks

Results of a first set of tests performed using the

large-scale ring-shear apparatus DPRi-6, devel-

oped at the DPRi, kyoto University (sassa 1997)

are described in detail by Boldini

et al

. (2009). The

DPRi-6 device is characterised by an inner diam-

eter of 250 mm, an outer diameter of 350 mm and

a maximum sample height of 150 mm.

Tests can be conducted in both drained and

undrained conditions, thanks to a water-leakage

tightness system formed by o-rings on the upper

loading platen, and bonding rubber edges on

the two confining rings of the lower rotary pair

(sassa

et al

. 2004). Pore pressure is measured by

two transducers located 2 mm above the shear

surface.

all the specimens were prepared using the dry

pluviation method with the aim of obtaining a very

loose initial configuration, similar to that produced

by the deposition process at sciara del Fuoco. in

all tests, saturation was obtained by exposing the

sample to a co

2

flux followed by a de-aired water

flux for a time (generally more than 12 hours) suf-

ficient to obtain a value of skempton's pore pres-

sure parameter

B

higher than 0.95.

Torque-controlled tests were performed in

undrained conditions and with free drainage at

the sample top. During the latter procedure excess

pore pressure can generate depending on material

behaviour and loading rate.

in both cases, samples were consolidated at a

normal stress of 230 kPa and a shear stress of

122 kPa. These values, calculated assuming that

the material is normally consolidated (Boldini

et al 2009), correspond to the lithostatic stresses

along the reconstructed slip surface of the sub-

marine slide, located at the average depth and

dip of 37 m and 28°, respectively. at the end

of consolidation, the dry unit weight ranged

between 16.6 and 17.2 kn/m

3

. The shearing stage

was carried out by applying a shear torque with a

loading rate of 55 Pa/s.

in undrained tests, the volcaniclastic mate-

rial experienced liquefaction, evidenced by an

abrupt increase in pore-water pressure up to values

100

80

60

SG (tested material)

40

A (in situ soil)

20

0

0.1

1

10

grain size (mm)

Figure 1. Particle-size distribution curves of the in situ

volcaniclastic soil (curve a) and tested material (sG).