Environmental Engineering Reference

In-Depth Information

jointed block and confinement on a fifth side was

available too. Unusually for jointed rock masses,

neither concave nor convex load-deformation curves

were produced: rather the load-deformation was

linear when performed across the part-columnar

part entablature jointing.

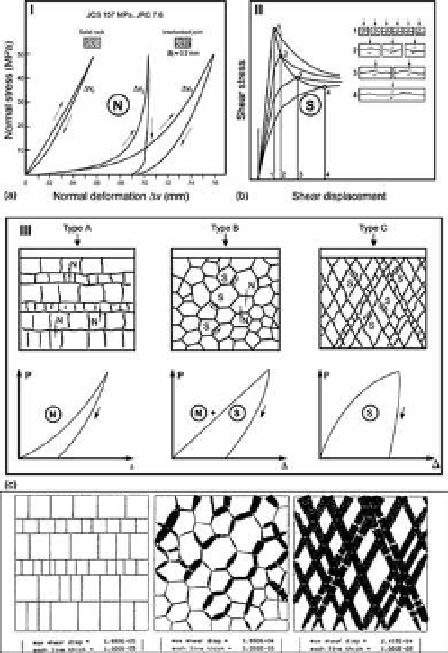

Figure 8 suggests how this may be due to the

combination of joint closure phenomena (concave)

and joint shearing tendencies (convex). UDec-BB

Figure 7. seismic and other physical measurements in

the face of the tunnel in basalt. Zimmermann and king,

(1985).

Figure 6. The vertical and horizontal ray-paths showed

great contrast due to the low stress across columnar

cooling joints.

The large contrasts in Vp values for the vertical

path (#1 to #2) and for the horizontal path (#3 to

#4) close to the opening (1.5 to 2.0 km/s difference)

are the most clear indication of the easily disturbed

columnar jointing. There is also some indication of

a tangential stress concentration effect: the back-

ground (far-field) velocity of about 5.4 to 5.8 km/s

appears to be elevated by about 0.5 m/s from about

4 to 8 m depth in the wall, with a lower background

velocity.

The authors registered no consistent trend in

RQD values with depth, but increased crack density

was seen close to the opening. The velocity reduc-

tions seem to be a product of blast-damage, stress

relief (and redistribution) and possible reduction

in moisture content. The authors noted water flow

from some of the horizontal holes during the tests,

and had originally assumed more or less saturated

conditions. however, Figure 7 does show a change

in saturation level.

These results are presented in order to emphasise

the possibility of drying out of some of the joints,

despite water flow from some of the holes. The

theoretical analysis of crack density did not appear

to be supported by the RQD measurements in gen-

eral, but is perhaps an expression of joint void ratio

changes, with the joints closest to the tunnel wall

showing the largest voids and therefore suggesting

an apparent (but false) increase in joint density.

a sophisticated heated block test was one of the

main components of the

in situ

testing at BWiP.

Flat jacks were used to load four sides of the large

Figure 8. conceptual explanation of concave, linear

and convex load-deformation curves obtained from in

situ testing, and UDec-BB modelling result showing

respective joint shearing magnitudes. Barton (1986), and

nGi modelling team.