Biomedical Engineering Reference

In-Depth Information

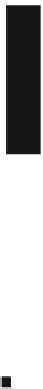

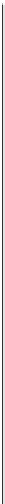

Fig. 19

Principal strain

distribution near the TMJ

screws

TMJ implant

8000

6000

4000

2000

Minimum strain

0

Maximum strain

−

2000

−

4000

−

6000

1 screw

2 screw

3 screw

4 screw

−

8000

hypotrophy to the bone, a strain higher than 4,000

strain is required according

to Roberts et al. [

60

], therefore it is expected that there will be bone growth or

hypotrophy on the first and last screws. To reduce the strains near these screws

more screws will need to be applied in the first part of TMJ implant (for example

parallel to the first screws). With this process, it will be possible to reduce strain and

promote the bone maintenance process. For the second and third screws, the strains

are below the hypotrophy limit presented by Roberts et al. [

60

] and then the bone

may grow.

This study proved that FE models can reproduce important information for TMJ

implant design. The knowledge obtained within this study provides a good basis

for other studies that can be performed with real bones for further development of

standardized FE pre-clinical tests for TMJ implants. Rigidity and structural integrity

of the implant are key issues to be observed.

5

Conclusions

This study proved that FE models can produce important information for TMJ

implant design. The knowledge obtained within this study provides a good basis for

further analyses that have to be performed with real bone characteristics to develop

standardized FE pre-clinical tests for TMJ implants. Rigidity and structural integrity

of the implant are key issues that can be observed.