Biomedical Engineering Reference

In-Depth Information

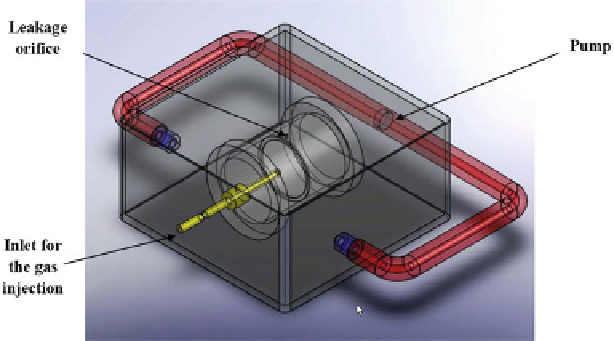

Fig. 15

Computer model used for the CFD analysis

5.1

Case 1: a 1 mm Hole

The analysis of the response time took in consideration the time that each curve

would take to start increasing in a constant angle. Figure

16

shows that the physical

experiment takes 5 s more to start increasing than the computational one. At the

beginning of the experiment the curves would differ by around 12% and after 180 s

the values are differing by around 4%. There is a similarity between the slopes of

the curves for the first 55 s but after this period there is considerable variation in the

curve up to approximately 140 s. Simulations with different meshes and step times

were performed to identify the reason for this result, but all of them would show a

similar behaviour very close to this same interval. One of the possible explanations

for this result is that the simulation in FloWorks does not appear to break up the

period of simulation evenly [

10

]. It appears that FloWorks uses different step sizes

for the iterations to calculate the results, and as these step sizes cannot be fixed, this

was leading to the unexpected results.

5.2

Case 2: a 2 mm Hole

The response time in this case is faster than case 1 for the physical experiment due to

the fact that the area of the hole now is bigger allowing more gas to exit the hole in a

shorter time. Figure

17

shows a similar behaviour to that of the previous experiment.

Again simulations with different meshes and step times were performed to see if any

changes would result, but all of them would show a similar behaviour very close to

this same interval (Fig.

18

).