Biomedical Engineering Reference

In-Depth Information

4

Open Surgery Experiments

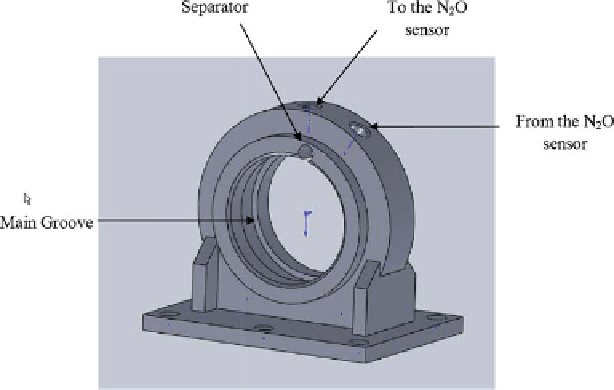

A second set of experiments were carried out to simulate an open surgical procedure

using a sensing ring around the tube. This simulates a closed shell as it is envisaged

would be used and is shown in Fig.

3

. This model was first created in Solid Works

and then built with on rapid prototype machine. It contains one outlet for the N

2

O

sensor and one inlet for air. The hole made just below the sensor inlet was used to

separate the groove in the centre of the ring in two parts, and to create a “directional

flow” between this groove and the tube that goes into the testing ring. The separator

was introduced to make the air flow in a clockwise direction around the ring pushing

the gas in the direction of the sensor outlet and would help to avoid a vacuum in the

experiment.

Referring to Figs.

4

and

5

,theN

2

O gas is injected through the injection tube into

the rigid pipe and it would escape through one of the leak holes indicated by the

small red circles, shown in Fig.

4

and marked with an angle in order to identify the

location of the leak. The gas then circulates in the groove between the testing ring

and the colon, and exits through the pipe to the N

2

O sensor inlet shown in Fig.

5

.

It then, passes through the pump, reaches the sensor, which reads the amount in

ppm increase over the time of the gas and transmits the information to the computer

through the Pico system. The gas is then pumped into the testing ring again through

the outlet of the N

2

Osensor.

However, some issues were found during the testing phase. One of them was

that there was a leakage between the groove and the pipe probably caused by

the separator, which was a piece of rubber from an O-Ring, or by an imperfect

attachment of the colon analogue into the testing ring leaving it slightly loose

Fig. 3

CAD model of testing ring for one sensor