Biomedical Engineering Reference

In-Depth Information

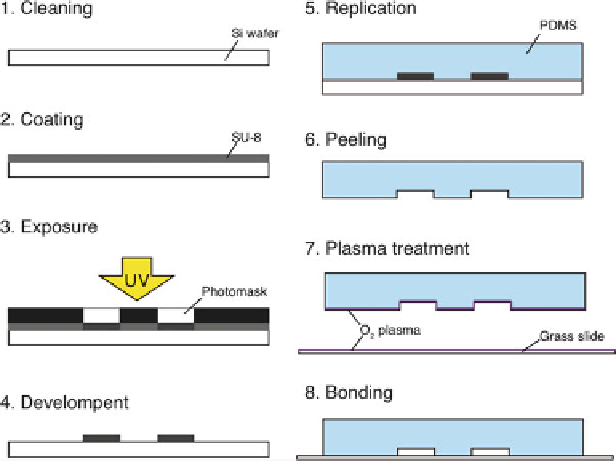

2.3 Fabrication of a Polydimethylsiloxane Microchannel

A standard soft lithography technique is widely used for fabricating microchannels

such as those with a stenosis [

8

] or with a bifurcation and confluence [

10

]. Here, as

an example, we outline the fabrication procedure using photoresist SU-8 and

polydimethylsiloxane (PDMS). SU-8, an epoxy-based photoresist, is widely used

for fabricating channel molds. It can sustain structures with high aspect ratios, so

that vertical sidewalls can be built easily. PDMS is a polymeric silicone with

excellent material properties for making microfluidic devices. Its good optical

transparency, good biocompatibility, accurate replication of fine and complex

geometries, high thermal stability, and low cost make PDMS one of the most

popular materials for microfluidic devices.

Figure

2.2

is a schematic of the procedure used for fabricating the microchannel.

First (Step 1, Fig.

2.2

) to enhance the adhesiveness of the photoresist on the wafer,

the surface of a silicon wafer was cleaned using piranha solution, which is a mixture

of sulfuric acid and hydrogen peroxide, to remove organic residues. After the

substrate was washed with deionized water to remove all traces of the cleaning

solution, the photoresist (SU-8 2075; Kayaku MicroChem, Tokyo, Japan) was

applied to the silicon wafer with a spin coater. The thickness of the photoresist

was controlled by adjusting the revolving speed of the spin coater (Step 2). Then,

the wafer was glued to a photomask on which the channel geometry had been

drawn. Finally, the wafer was exposed to ultraviolet light (Step 3) completing the

silicon mold with the microchannel pattern (Step 4).

Fig. 2.2

Procedure for fabricating a PDMS microchannel

Search WWH ::

Custom Search