Biomedical Engineering Reference

In-Depth Information

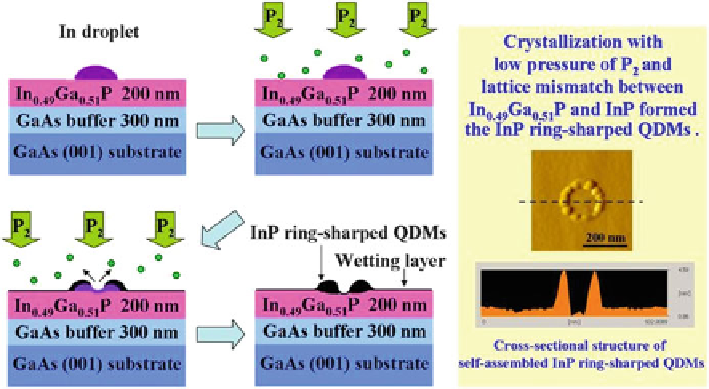

Fig. 2.8

Schematic displays of each processing steps of InP ring-shaped QDMs on InGaP/GaAs

by droplet epitaxy technique

is observed, compared to the effect of primary step in the deposition process.

Uniform QD is optimized at a crystallization temperature of 200

◦

C.

In several series of experiments on droplet epitaxy, we can optimize the growth

conditions to give fine InP ring-shaped QDMs by setting the deposition temperature

and crystallization temperature at 250 and 200

◦

C, respectively. The ring shape

and density as well as the dot size are mainly defined by indium thickness during

deposition step.

The number of QDs per QDM is another feature that is needed to be controlled

for QD device applications. QDMs with eight QDs in ring shape are one of our

aims in fabricating InP ring-shaped QDMs. This octa-quantum dot molecule will be

a quantum dot set applicable for extended quantum dot cellular automata (EQCA).

The concept of QCA will be discussed in detail in the following section.

When InP ring-shaped QDMs are capped by 100 nm thick InGaP for analytical

photoluminescence measurement and for multi-stacked nanostructure, ring-shaped

QDMs should be little affected by InP/InGaP matrix by using first InGaP capping

layer grown by migration enhanced epitaxy technique at a low temperature of

300

◦

C. To confirm the existence of ring-shaped QDMs, the sample is then prepared

for TEM observation of their cross-sectional profiles. TEM image of InP ring-

shaped QDMs grown at a deposition temperature of 250

◦

C and a crystallization

temperature of 200

◦

C with indium deposition rate of 1.6 ML/s and indium thickness

of 3.2 ML is shown in Fig.

2.11

. TEM image can give actual dimensions of the

nanostructure as follows. The outer and inner ring diameters are 140 and 80 nm,

respectively. The basement of QD is approximately 40 nm with the dot height of

few nm. These data are collected from the cross-sectional profile of the topmost

nanostructure which has no thermal annealing effect by the capping process.