Biomedical Engineering Reference

In-Depth Information

2.4

Structural Evolution from In Droplets to InP

Ring-Shaped QDMs

Indium droplets are starting elemental materials deposited on InGaP buffer layer at

the beginning step of droplet epitaxy. Indium thickness (in ML), deposition rate (in

ML/s), and deposition temperature (in

◦

C) will define the droplet size and droplet

density. The deposition temperature is a key parameter to control the droplet size

and droplet density. At low deposition temperature, the droplet size is small but the

droplet density is high. When the deposition temperature is higher, nearby small

droplets will merge with each other resulting in a bigger droplet size, but the droplet

density will become lower. The deposition rate will also affect the droplet evolution

in a more complicated way. The indium thickness will keep the droplet density

saturated with nominal droplet size.

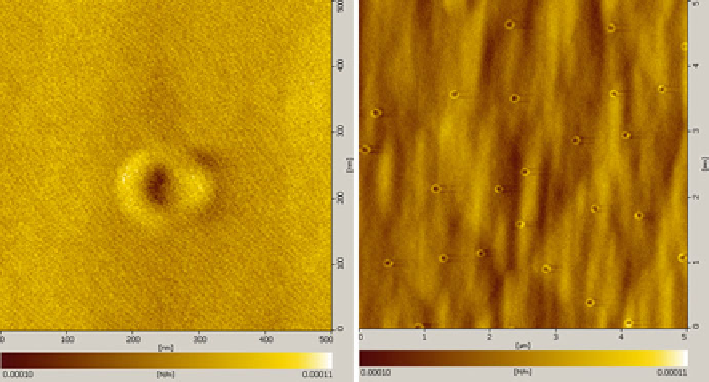

When the crystallization of indium droplets is performed under P pressure, In

droplets transform to InP QRs and InP ring-shaped QDMs, respectively. At small

indium thickness, In droplets will be crystallized only to InP QRs as shown in

Fig.

2.5

. The ring has an isotropic shape and a small ring diameter. When indium

thickness increases, InP QRs are transformed to InP ring-shaped QDMs as shown

in Fig.

2.6

. The ring diameter becomes longer with an increasing number of QDs

and with a bigger dot size on the ring.

Figure

2.7

shows evolution from InP QRs to InP ring-shaped QDMs when

indium thickness is varied from 1.6 to 6.4 ML (deposition temperature 250

◦

Cand

crystallization temperature 200

◦

C). Ring diameter, dot size, number of QDs per

QDM, and density of ring-shaped QDMs are increased due to larger supply of

Fig. 2.5

AFM image of InP QRs grown from In thickness 1.6 ML (crystallization temperature

200

◦

C)