Biomedical Engineering Reference

In-Depth Information

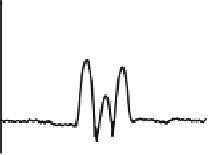

a

d

g

6

3

0

0

250

500

750

Distance (nm)

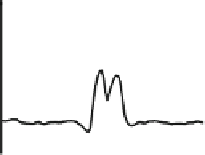

b

e

h

6

3

0

0

250

500

750

Distance (nm)

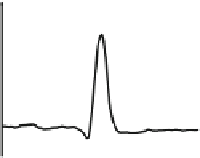

c

f

i

6

3

0

150 nm

0

250

500

750

Distance (nm)

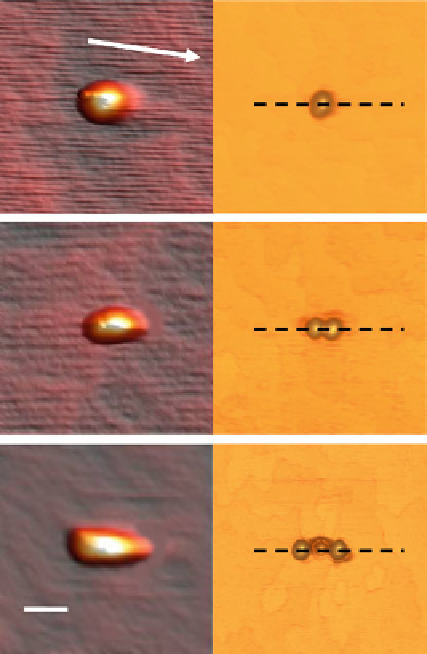

Fig. 1.16

AFM topography images of initial oxide dots with lateral dimensions 160 nm

×

160 nm

(

a

)

and

oxide

lines

fabricated

closely

along

[1 1 0]

direction

with

lateral

dimensions

160 nm

270 nm (

c

). The obtained results after deposition of 1.5 ML

of InAs on samples without GaAs buffer layer growth are shown in (

d

-

f

). The profiles along the

lateral arrangement of QDs are depicted in (

g

-

i

). Adapted from [

22

]. Copyright 2009 Institute of

Physics

×

230 nm (

b

) and 160 nm

×

the B-slope areas inside the stripes, the incorporation rate of In atoms inside this

pattern increases, which finally determines the selectivity of the pattern for the

InAs nucleation process. Taking into account these findings, it can be inferred

that the amount of InAs (i.e., number of QDs formed inside the nanohole) can

be controlled by previously designing the nanohole size and shape during the

lithography process. Figure

1.16

shows AFM images of the initial oxide dots with

lateral dimensions 160 nm

160 nm (Fig.

1.16

a), and oxide lines fabricated closely

along the [1 1 0] direction with lateral dimensions 160 nm

×

×

230 nm (Fig.

1.16

b),

and 160 nm

270 nm (Fig.

1.16

c). The height of both, the oxide dots and the lines,

is about 8 nm. The results obtained after deposition of 1.5 ML of InAs on these

×