Biomedical Engineering Reference

In-Depth Information

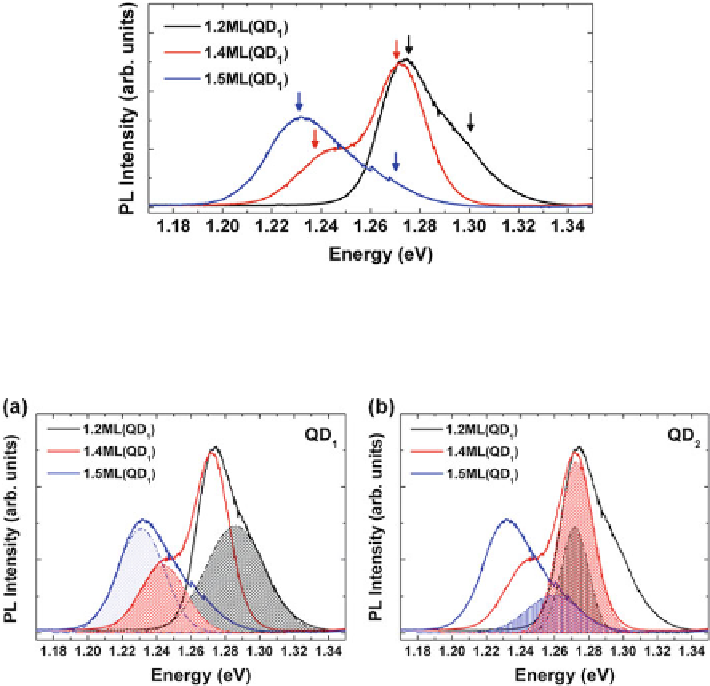

Fig. 1.4

Photoluminescence spectra for the three vertical QDMs designs fabricated.

Black

,

red

,

and

blue curves

correspond to 1.2, 1.4, and 1.5 ML of InAs deposited into the nanoholes,

respectively. The

arrows

in the figure point out the two families of QDs formed on each sample.

Adapted from [

31

]

Fig. 1.5

Photoluminescence emission (

filled areas

)ascribedto(

a

)QD

1

and (

b

)QD

2

nanostruc-

tures. A clear tuning effect on the emission of QD

1

is obtained independently of the emission of

QD

2

, which shows similar emission for all the samples. Adapted from [

31

]

InAs increases, the emission energy of QD

1

decreases, further demonstrating the

preferential nucleation of InAs into the nanoholes. Analogously, Fig.

1.5

bshows

as filled areas the three PL emission spectra ascribed to the nanostructure QD

2

.

In this case, the emission energy is similar in all cases indicating that the size

of QD

2

remains constant despite the varying amounts of InAs material nucleated

underneath. The emission energies ascribed to QD

1

and QD

2

in these PL curves are

listed in Table

1.1

. The arrow in this table highlights the tunability of the energy

emission of QD

1

as a function of InAs material deposited into the nanoholes.

Altogether, these results show that the preferential nucleation of controllable

amounts of InAs material into a nanoholes template formed by the droplet etching

technique allows for a deliberate designing of symmetric or asymmetric vertical

QDMs where the emission of one QD can be tuned with independency of the other.