Biomedical Engineering Reference

In-Depth Information

Sugar-leached

PLCL scaffold

MSPs

PLCL

Silicon wafer

Neodymium magnet

d)

a)

c)

b)

Figure 8.17

Fabrication process of a sheet-like PLCL scaffold.

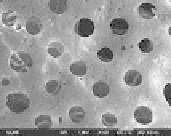

MSPs were used to fabricate a sheet-like scaffold. Figure 8.18

shows an overview and surface conigurations of fabricated scaffold.

The self-assembly of MSPs with controlled diameter contributed to

generating effective interspaces where polymer solution iniltrated.

The vacuum-assisted iniltration of PLCL solution was successful and

polymer structure was maintained after whole fabrication process.

The porous coniguration was visible to naked eyes owing to large

pore size. Circular holes observed in Figs. 8.18(b-c) were due to the

contact between MSPs and silicon substrate at the stage of magnetic

attraction. Pores of less than 50

μ

m were also scattered sparsely on

the surface (Fig. 8.18(c)). These small pores are probably due to the

reaction of phase separation among PLCL, chloroform and some

residual hexane.

5 mm

Circular

Hole

5 mm

a) Sheet-like scaffold

500 m

b) Microscope image

of surface

c) SEM image of surface

Figure 8.18

Surface coniguration of sheet-like PLCL scaffolds captured by

optical and electronic microscope.

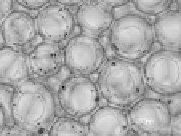

MSPs 1, MSPs 2 and MSPs 3 shown in Fig. 8.15 were also used to

fabricate PLCL scaffolds. In the same way on previous method, those

sugar particles were cast to PLCL polymer. Figure 8.19 shows the

surface conigurations of PLCL scaffolds cast from MSPs 1, MSPs 2

and MSPs 3. The average diameter and SD of pore size is qualitatively

very close to those of MSPs.

Search WWH ::

Custom Search