Biomedical Engineering Reference

In-Depth Information

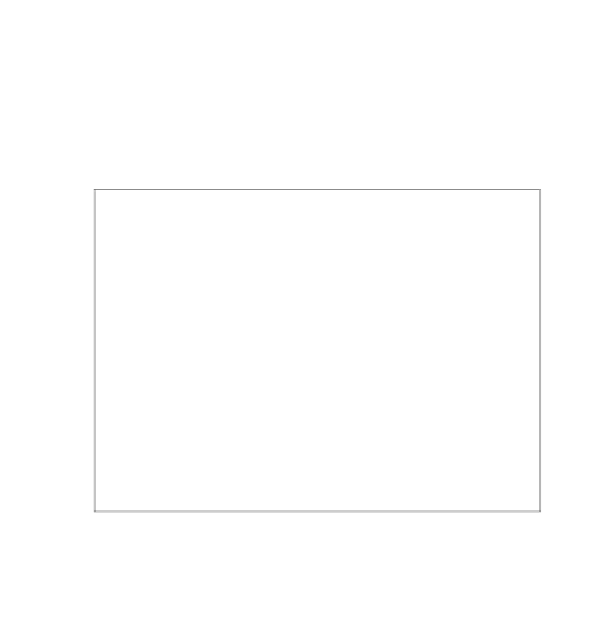

(i) Larger sieving range yielded MSPs with larger SD of diameter

while smaller sieving range yielded almost uniform size of

MSPs.

(ii) The diameter of all the MSPs were truly in the sieving range.

500

n=20

400

300

200

100

0

MSPs 1

150-500

MSPs 2

MSPs 3

Sieving range (Mm)

Figure 8.16

Relation between sieving range and diameter of MSPs. The

diameter of all the MSPs was truly in the sieving range.

8.7.2

Fabrication of Porous PLCL Sheet-Like Scaffolds by

Magnetic Sugar Leaching

Figure 8.17 shows the fabrication process of PLCL sheet-like

scaffolds. First, a specially coated silicon wafer was dried in a hot

oven (Fig. 8.17(a)). MSPs fabricated in the previous section were then

attracted to form an assembly by a neodymium magnet (magnetic

lux density: 0.122

T) located under the wafer (Fig. 8.17(b)). Then

polymer solution (PLCL 10

w% in chloroform) was dropped on

MSPs and vacuum was applied to ill the interspace between each

particle (Fig. 8.17(c)). After the complete evaporation of chloroform

and removal of the magnet, the composite with silicon wafer was

soaked in water to dissolve sugar. Finally, we obtained porous and

biodegradable scaffolds with well-connected pores (Fig. 8.17(d))

[42].

Search WWH ::

Custom Search