Biomedical Engineering Reference

In-Depth Information

(stretching velocity: 0.3

mm/s, shape of specimen: JIS Z2201). After

measuring stresses and strains of 15 scaffolds, Young's modulus of

each scaffold was calculated using

s

Pl

E

ss

(8.1)

E

ltd

where

E

,

P

,

l

,

E

l

,

t

, and

d

are the Young's modulus, stress, length,

variation of length, thickness, and width of the sheet, respectively. At

each experimental condition, six samples were measured to obtain

standard deviation (SD). Therefore, 90 (5

×

3

×

6) samples were

tested.

10000

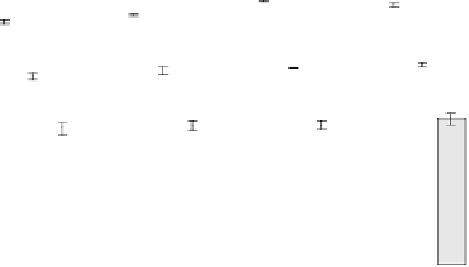

PLCL 10w% in Chloroform

PLCL 5w% in Chloroform

PLCL 3w% in Chloroform

1000

100

10

1

1

2

3

4

Pulling-up speed (mm/s)

Figure 8.5

Relation between pull-up velocity and thickness of dip-coated

PLCL membrane (

n

= 5 for each bar, vertical axis : logarithmic

scale, PLCL : NaCl = 6 : 4

wt%).

Figure 8.6 shows an experimental setup used to measure Young's

modulus. A commercial dip coater was modiied to be a tensile tester

by attaching a load cell. The load cell was connected to a force gage,

which was also connected to a laptop. The pull-up motion of a dip

coater was used to stretch specimens of PLCL sheet-like scaffolds

(pull-up speed: 0.1

mm/s). Time series variation of tensile force was

recorded in PC and was subsequently converted into a stress-strain

curve. Specimens were stretched until the tensile force reached 5

N.

Search WWH ::

Custom Search