Biomedical Engineering Reference

In-Depth Information

and regular, unlike natural extracellular matrix structure. Thus, alternatively, microspheres

can be preformed from polymers and then sintered together to form three-dimensional scaf-

folds, creating a more random porosity (Figure 5.14).

Solid freeform fabrication is also used to make biomaterial scaffolds (in addition to being

used for rapid prototyping of automotive or aerospace industry parts). Some techniques fall

under the umbrella of “solid freeform fabrication.” Stereolithography is one technique that

uses a focused laser that follows a pattern dictated by computer-assisted design drawing to

selectively cure only certain areas within a thin layer of liquid polymer. The depth of the

liquid is raised around the part being fabricated, and the laser is again sent on a com-

puter-assisted path to form the next layer of the component. This is repeated over and over

again to produce a complex three-dimensional shape. Similarly, a technique known as 3-D

printing can be used to create porous scaffolds or complex shapes layer by layer, this time

using a print head to deposit “glue” over computer-specified areas of a powder bed. After

all of the layers have been “printed,” the final part is picked up, and the unbonded particles

fall away, revealing the three-dimensional component. Pieces of replacement bone have

been made using these techniques with computer assisted tomography (CAT) scans of

x-ray images. The features of the scaffolds are limited to 10-1,000

m with these techniques,

m

which have been used to prepare polymer and ceramic scaffolds.

A scaffold fabrication technique that does result in a nanofibrous polymeric structure

similar to the extracellular matrix is electrospinning. Electrospinning is the same technique

used to make cotton candy. A molten polymer solution is drawn out from a nozzle by an

A

B

C

D

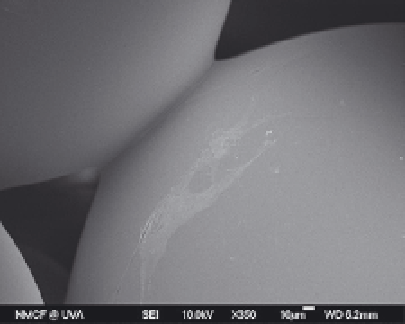

FIGURE 5.14

An example of a three-dimensional heat-sintered polylactide-co-glycolide microsphere scaffold.

These 100 percent interconnected porous scaffolds offer mechanical properties in the midrange of human trabecu-

lar bone with 30-35 percent porosity and an average pore diameter of 100-150

m. Optical micrographs (a) repre-

sent the top view and (b) the side view of the scaffold. SEM micrographs (c) and (d) show macroporous structures

and bonding between adjacent microspheres.

m

Images courtesy of the Cato T. Laurencin Laboratories, University of

Connecticut Health Center.