Biomedical Engineering Reference

In-Depth Information

2 Preparation of Biodegradable Polymeric Nanoparticles

2.1 PLGA Nanoparticles

Biodegradable polymeric nanoparticles have attracted much attention for their

potential in biomedical applications, such as drug, gene, and vaccine delivery

systems. The biodegradation rate and the release kinetics of loaded drugs can be

controlled by the composition ratio and the molecular weight of the polymer and

block/graft copolymers [

26

-

28

]. Furthermore, by modulating the polymer

characteristics, one can control the release of a therapeutic agent from the

nanoparticles to achieve a desired therapeutic level in a target tissue for the required

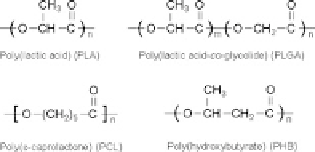

duration for optimal therapeutic efficacy. The commonly used biodegradable

polymers are aliphatic polyesters such as poly(lactic acid) (PLA), poly(glycolic

acid) (PGA), poly(

e

-caprolactone) (PCL), poly(hydroxybutyrate) (PHB) and their

copolymers (Fig.

2

)[

29

]. In particular, poly(lactide-

co

-glycolide) (PLGA) has been

the most extensively investigated for developing nano- and microparticles

encapsulating therapeutic drugs in controlled release applications [

30

-

32

]dueto

their inherent advantages. The copolymers have the advantage of sustaining the

release of the encapsulated therapeutic agent over a period of days to several weeks.

As polyesters in nature, these polymers undergo hydrolysis upon administration

into the body, forming biologically compatible and metabolizable moieties (lactic

acid and glycolic acid) that are eventually removed from the body by the citric

acid cycle.

Several methods have been reported for the preparation of biodegradable

nanoparticles from PLGA, PLA, and PCL by dispersing preformed polymers.

Emulsion solvent evaporation techniques are frequently used to prepare nano-

and microparticles [

33

,

34

]. The polymer is dissolved in an organic solvent like

dichloromethane, chloroform, or ethyl acetate and then emulsified into an aqueous

solution to create an oil-in-water (o/w) emulsion by using a surfactant such as poly

(vinyl alcohol). After the formation of a stable emulsion, the organic solvent is

evaporated by increasing the temperature under pressure (Fig.

3

). The effect of this

process is variable, depending on the properties of the nanoparticles. Often,

surfactants are used to stabilize the nanoparticles in aqueous solution in order to

prevent the aggregation and/or precipitation of water-insoluble polymers. However,

adequate removal of the surfactant remains a problem, and surfactant molecules are

sometimes harmful in biomedical applications.

Fig. 2 Chemical structures

of biodegradable polyesters

used for preparation of

nanoparticles