Biomedical Engineering Reference

In-Depth Information

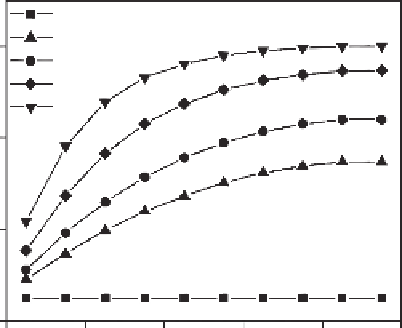

m = 0

m

= 0.05

2.1

m

= 0.1

m = 0.3

m = 1

1.9

1.7

1.5

0

0.2

0.4

PVDF length

0.6

0.8

1.0

Figure 3.19

The output voltages of 10 equal biaxial PVDF sensing elements evenly positioned

along the

x

-axis. While the applied load is kept constant, the friction coefficient is varied between

0 and 1. The horizontal axis is normalized by half the length of PVDF film, and hence 0 represents

the center of the film and 1 denotes the PVDF edge at

x

=15mm

surfaces had to be estimated. Once the friction coefficients of the surfaces on both sides

of the PVDF film were experimentally determined, the characterized surfaces were used

in another experimental setup to record the output voltage of the PVDF film.

3.9.1 Surface Friction Measurement

In order to measure the static friction coefficient of test surfaces, as shown in Figure 3.20, a

conventional experimental setup was designed and implemented. Extreme care was taken

to reduce unwanted friction forces. The minimum force increment steps were 0.01 N and

the force applied to the surfaces was in the range 2 - 10 N. Some of the selected surfaces

were made of standard abrasive papers. In addition, other available surfaces such as sta-

tionery paper or Plexiglas were also tested. To achieve low friction surfaces, lubricants

were used. However, because of various problems, the application of oils did not yield

satisfactory results. The first difficulty was the stickiness of the smooth surfaces in the

presence of the oil. The second was maintaining the uniformity of the lubrication condi-

tions, such as the thickness of the oil film present for different applied loads. To eliminate

these difficulties, a couple of readily available dry lubricants were tested. Normally these

materials can be sprayed onto the target surfaces.

Alternatively, low-friction materials, such as Teflon tape, which can be cut and pasted

on the surface, can be used. For the present study, 555 Silicon Dry Film Lubricant

and a Molykote 321 Dry Film Lubricant from Dow Corning were used. In addition, a

PTFE adhesive tape from Nitto Denko was tested. The data recorded for silicon dry film

was not repeatable because the silicon film peeled off easily during the experiments.

The selected abrasive papers ranged in grade between very fine (grade 2000) to very

rough (grade 240). Since one of the surfaces in the tests was PVDF, always one surface