Biomedical Engineering Reference

In-Depth Information

Force

Force

measurement

FSR

LUT

DAQ

input

PID

controller

DAQ

output

Actuator

& driver

Error

Limitter

Shaft position

measurement

Shaft Position

(a)

LUT

Output

Force

measurement

Input

PID

controller

(b)

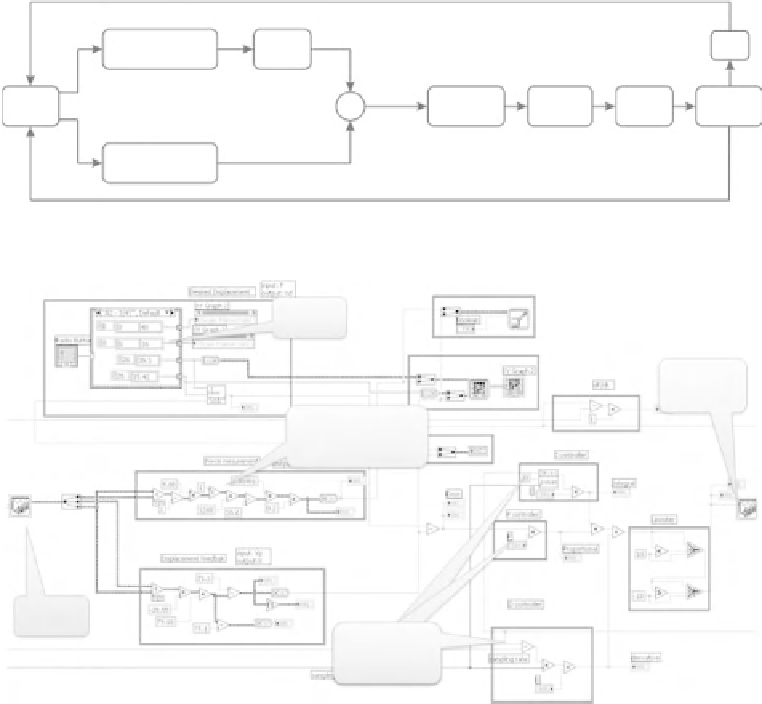

Figure 11.18

(a) The block diagram of the completer system. (b) The block diagram simulated in

the LabVIEW programming environment. LUT: lookup table that contains the force - displacement

data of the target material

The rate of applying the force is also important for the feel of softness. Since the

rate of the force in the original force - deformation data collection was applied slowly, the

error becomes negligible, as depicted in Figure 11.24. However, when the force is applied

suddenly, the error becomes larger. Figure 11.24 shows the real and desired force - position

curves for two different speeds. In the first instance, the force is applied slowly, whereas

in the second case it is applied quickly. From this, it can be seen that the error in the first

case is much less than in the second case. In this study, the force - displacement curve

for the original elastomers was collected only at slow speed. However, in order to obtain

a more comprehensive database on the elastomer, compression tests were conducted at

different force or displacement rates and, based on the user speed at the tactile display

side, the corresponding curve was used.