Biomedical Engineering Reference

In-Depth Information

Actuator model

Plant

86

a

2

.

s

2

+

a

1

.

s

+ 4

1

1

u

y

Figure 11.14

The plant is a second-order linear system

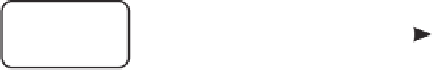

Controller

+

PID

u

y

-

Step

Plant and actuator

Scope

1

*Tunable Variables are PID gains,

Kp

,

Ki

and

Kd

.

Out

1

Figure 11.15

The closed-loop system

The error is defined as the difference between step input and output. The cost function

to be minimized (

J

) is the total square error from 0 to 100 seconds (see Equation 11.21).

100

y (t)

u(t)

2

d

t

J

=

−

(11.21)

0

The variables are the parameters of the PID controller,

J

(

K

)=

J

(

K

p

,

K

I

,K

D

). In discrete

cases, Equation 11.21 is written as:

N

J

K

P

,K

I

,K

D

=

y(k)

u(k)

2

−

;

k

=

1

, ... ,N

(11.22)

k

=

1

where:

100

T

s

N

=

(11.23)

In which

N

is the total number of samples in 100 seconds and

T

s

is the sampling period.

Having the number of samples (

N

) and sampling period (

T

s

), the objective of the

optimization problem is to find PID controller parameters for which

J

(

K

) is minimized.

The Matlab routine '

lsqnonlin

' was used to perform least-squares fit on the tracking of

the output. The tracking was performed via an M-file function '

tracklsq

,' which returns

the error signal, the output was computed by calling '

sim

,' minus the input signal 1(unit

step). The code for '

tracklsq

' is shown in Appendix 11.A.