Biomedical Engineering Reference

In-Depth Information

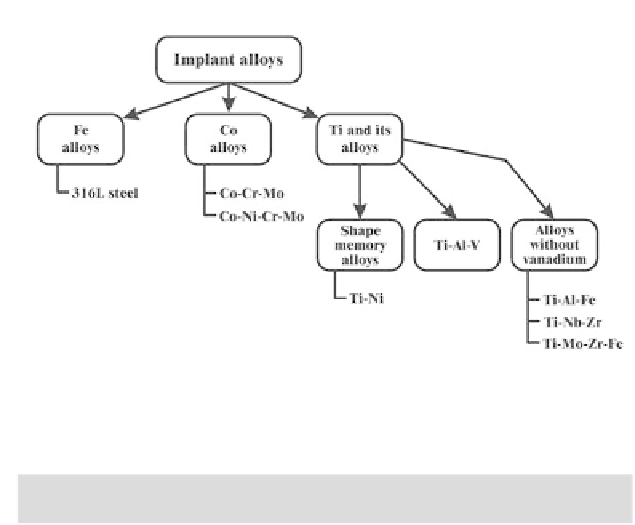

Figure 3

.

2

Implant alloys.

Ta b l e 3

.

5

Mechanical properties of metallic biomaterials [15, 16]

Ultimate tensile

strength [MPa]

Fatigue

strength* [MPa]

Elongation at

fracture [%]

BF

[*10

-3

]

E

[GPa]

Metals

CrNi-steels 490-690

200-250

>40

1-12 210

CoCr-alloys 800-1200

550-650

8-40

1.5-2.3 200

CP-Ti

390-450

150-200

22-30

1.4-1.9 100

Ti-6Al-4V 930-1140

350-650

8-15

3.0-5.6 115

* Rotating bending fatigue.

Unfortunately, these materials have exhibited tendencies to fail

after long-term use due to various reasons such as high modulus

compared to that of bone, low wear and corrosion resistance, and

lack of biocompatibility. The various causes for revision surgery are

depicted in Fig. 3.3 [46].

From the biomechanical point of view, it is desirable to have

a Young's modulus of metallic biomaterials comparable to that

of the cortical bone in order to achieve a good load transfer from

the implant into the bone, leading to a continuous stimulation of

new bone formation (isoelastic material). In order to provide an

E

modulus comparable to that of compact bone (10

−

15 GPa), porous

sintered implants are required. The reduction of Young's modulus

as a function of the porosity can be calculated by means of equation

(3.2) [5]: