Biomedical Engineering Reference

In-Depth Information

researchers [15, 26, 30, 31, 58]. Reducing the danger of inlammations

and avoiding the need for repeat surgery by using temporary,

biodegradable metallic implants and at the same time capitalizing

on their good mechanical strength is, indeed, a very attractive

possibility. Many groups worldwide have rapidly moved into this

area. Despite some problems with biotoxicity of certain alloying

elements, structural Mg alloys have been used in biocompatibility

tests, both

in vitro

and

in vivo

. Clinical tests have demonstrated

the viability of Mg alloys as stent implant materials. Recent results

supported by the published work suggest, however, that

in vivo

tests are indispensable already at this stage, as biocompatibility

of Mg alloys

in vitro

does not fully represent what happens

in vivo

[15, 58].

Recent work has demonstrated that bulk grain reinement

techniques, such as equal-channel angular pressing, are potent tools

to improve the fatigue strength and the bio-corrosion resistance of

common structural Mg alloys [55]. We are exploring the ways to

further improve the properties of Mg based alloys and make them it

for applications in bioresorbable implants.

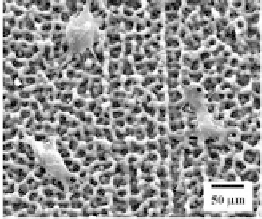

However, bulk grain reinement may be insuficient to bring the

bio-corrosion rate down to the levels required by the clinical needs.

A natural way to contain corrosion of Mg and achieve controllable

corrosion rates is by surface modiication, particularly through

smart coating design. For example, corrosion of Mg alloys is retarded

markedly when a thin MgF

2

layer is formed on the surface in a

luoridation process. Furthermore, when a bioactive material, such

as hydroxyapatite, is deposited on top of the MgF

2

layer, both the

corrosion resistance and biocompatibility are enhanced signiicantly

(Fig. 13.11).

Figure 13.11

Coating layers of MgF

2

and hydrohyapatite (HA) on Mg

(left) and osteoblast cells attached on the surface of Mg

coated with MgF

2

and HA (right) [55].