Biomedical Engineering Reference

In-Depth Information

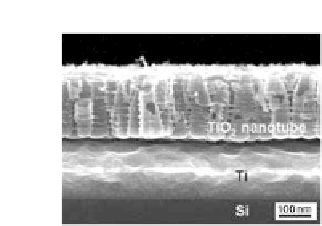

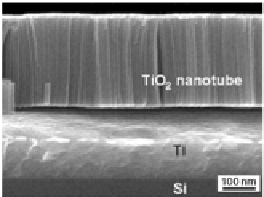

Figure 9.51

SEM images of nanotube/Ti/Si anodized in aqueous solutions

(1 M Na

2

SO

4

+ 0.2 M C

6

H

8

O

7

· H

2

O with the addition of 0.4

wt.% NaF) at 20 V for 600 s (in left) and in glycerol electrolyte

(0.5 wt.% NH

4

F in glycerol) at 10 V for 2 h (in right) [111].

Figure 9.52A presents the thickness of the nanotube as a

function of the anodization time for the aqueous and glycerol

electrolyte. Higher anodizing voltage leads to longer nanotubes for

both electrolytes. Yang

et al

. [111] calculated the conversion ratio

L

/

T

, where

L

is the length of the nanotube and

T

is the thickness

of the consumed titanium (Fig. 9.52B). They found that conversion

ratios of the samples anodized in glycerol electrolyte are more than

1 and those in aqueous electrolyte are nearby 1. The volume

expansion occurs when the titanium metal converts into titanium

oxide. They concluded that a violent etching of nanotube

simultaneously occurred at the interface of electrolyte and

nanotube surface during anodization. The etching made the inal

titanium nanotube short. The anodization in aqueous electrolyte

has a faster growing rate and a larger loss in length of nanotube

than in the glycerol electrolyte due to higher diffusivity of ions.

Figure 9.52

(A) Length of the nanotube as a function of the anodization

time for the aqueous and glycerol electrolyte. (B) Conversion

ratio,

L

/

T

(where

L

is the length of the nanotube grown by

anodization and

T

is the thickness of the consumed titanium)

[111].