Biomedical Engineering Reference

In-Depth Information

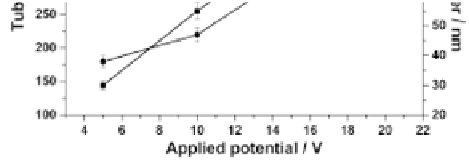

combined with tube length from 20 nm to 1 μm [4]. The diameter

and the length depend linearly on the voltage, too. So, by careful

choice of anodic oxidation parameters, it is possible to control the

growing nanotubes.

Figure 9.50

Dependence of the tube diameter and length on the applied

potentials [53].

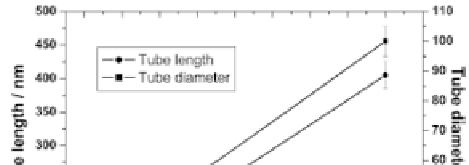

Yang

et al

. [111] showed the formation of nanotubular Ti on

sputtered material (Fig. 9.51). They deposited titanium layers of

863 nm thickness on silicon substrates by DC magnetron sputtering.

The anodization procedure consisted etching in aqueous solution

(1M Na

2

SO

4

+ 0.2M C

6

H

8

O

7

· H

2

O with the addition of 0.4 wt%

NaF) and glycerol electrolyte (0.5 wt% NH

4

F in glycerol). The

potential was ramped by 0.1 V/s from the ocp to 5-30 V and

then kept at constant value for various times. After anodization,

the standard rinsing with deionized water and drying with a

nitrogen stream was applied. Much higher current densities are

observed in the aqueous electrolyte than in the glycerol electrolyte,

because higher diffusivity and concentration of ions in the aqueous

solution. The nanotubes are open on the top and closed at the

bottom [111]. The morphologies of nanotube anodized in glycerol

electrolyte were different from those in aqueous electrolyte

(Fig. 9.51). The outer diameter of the nanotubes increases with

the increasing anodization voltage for both types of electrolytes. The

nanotube diameter was remarkably affected by the electrolyte and

at the same applied voltage; the nanotubes with 100 nm and 40 nm

diameters were obtained in the aqueous and glycerol electrolyte,

respectively.