Biomedical Engineering Reference

In-Depth Information

Porous Ti compacts, made by powder metallurgical process,

have porosities ranging from 5.0 to 37.1 vol% [65]. In these porous

Ti compacts, the rough surface depends on Ti initial powder size, so

the porosities and mechanical properties of porous Ti compacts can

be controlled by changing powders size and sintering conditions. Oh

et al

. found that Young's modulus and bending strength of porous Ti

compacts having the porosity approximately 30 vol% are close to

those of human cortical bone [65]. Increasing porosity results in a

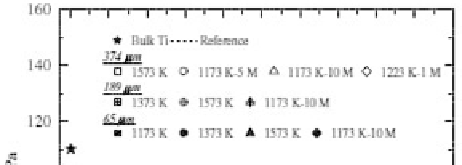

signiicant decrease in Young's modulus (Fig. 9.1).

Figure 9.1

Young's modulus of sintered porous Ti compacts as a function

of porosity. Porous Ti compacts sintered with applied pressure

are abbreviated as temperature (K)-pressure (M) [65].

The Ti metal in all cases during processing (sintering, heat

treatment, and etching) in the oxygen-containing atmosphere

spontaneously forms a protective TiO

2

layer. When the Ti implant is

inserted into the human body, the surrounding tissues directly contact

the TiO

2

layer on the implant surface. The surface characteristics

of the TiO

2

layer determine the biocompatibility of the Ti implant

[112] and it is important to increase the biocompatibility of the