Biomedical Engineering Reference

In-Depth Information

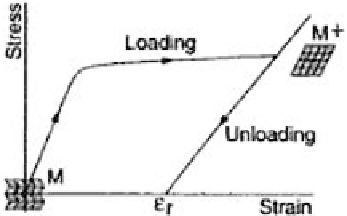

Similar reaction occurs during unloading. Material tends to

reveal almost linear relation of stress to strain when the level

of decreasing stress exceeded

σ

As

, and it starts a reversible

transformation from martensite to austenite. It is critical to have a

temperature range, which has to be considered for fully reversible

transformation.

In a high-temperature regime, where the temperature of

material is maintained above

A

f

, fully shape recovery is observed

and during unloading, this phenomenon is call pseudoelasticity or

transformational superelasticity.

During the full cycle of pseudoelastic transformation,

comprehended as austenite to martensite and reverse martensite

to austenite, we deal with generating in stress to strain system —

hysteresis curve, which is a result of the energy dissipation during

process. The curve's shape and values of stress levels strongly

depend on the material and measurement conditions.

For the temperature range of thermodynamic stability of

martensite phase, beneath

M

f

during loading, macroscopic change

of shape occurs as a result of detwinning mechanism. During

unloading, deform detwinned structure of martensite phase retains

a residual strain in the form of elongation

ε

r

as shown in Fig 8.15.

Figure 8.15

Stress to strain relation during loading for SMA at

thermodynamic stable martensite temperature range [41].

This low-temperature behavior is call

quasiplasticity

as

opposed to plastic deformation, characterized by permanent

deformation of structure. After heating the material in temperature

range higher than

A

f

, the accumulate strain is removed from

the structure and the reversible transformation to austenite is

achieved as shown in Fig. 8.16. This behavior is called shape memory

effect (SME) and will be discussed now.