Biomedical Engineering Reference

In-Depth Information

the transformation ends is denoted by

M

f

. Subsequent heating starts

reversible transformation from martensite to original symmetric

crystallographic state of austenite phase, and similarly

A

s

and

A

f

are

characteristic temperatures (Fig. 8.13).

8.4.2

Mechanically Induced Transformation

Apart from temperature dependence, phase transformation in

material can be induced by the applied loads as it has been mentioned

earlier.

At the applied mechanical load, the transformation of

the austenite structure generates only the type of martensitic

structure variants that reduce stress. When the loads are applied

to the martensitic grain structure, most favorable variants are

generated from the existing structure of different variants that lead

to the situation mentioned earlier and thus create the detwinned

form of martensite. This phenomenon is called reorientation. Also

essential in this point of discussion is to introduce the characteristic

M

d

temperature, deined as the value above the martensitic

mechanically induced transformation cannot occur; it is usually

25-50°C higher than

A

f

.

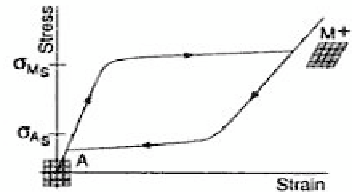

For the temperature range of thermodynamic stability of the

austenite phase, above

A

f

and beneath

M

d

during loading, nearly

linear relation between stress and strain occurs — the variants of

martensite that reduce stress are generated. When the level of

σ

Ms

is exceeded, the transformation of austenite to martensite begins.

The structure starts to accumulate energy in elongation form, which

manifests as a macroscopic change of microstructure. It undergoes

further transformation — reorientation into the detwinned form of

martensite

M

+ (Fig 8.14).

M+

σ

Ms

σ

As

A

Strain

Figure 8.14

Stress to strain relation during loading for SMA at

thermodynamic stable austenite temperature range [41].