Biomedical Engineering Reference

In-Depth Information

that such procedure, called training in SMAs, can take much longer

time, and deformation rates from the initial to the deformed shape

assume a much lower value. Also for other types of external stimulus,

understandable as different molecular switch reaction, polymer will

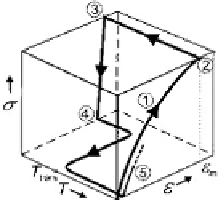

behave similarly as shown in Fig. 8.9.

Figure 8.9

Schematic representation of cyclic thermomechanical behavior

[20].

The irst step brings an elongation

ε

m

of the specimen that is

realized in the temperature range above

T

trans

, the molecular switch

is open and the stress-induced reaction of material is not blocked by

its bonds. After that, the strain is maintained to allow the relaxation

of the polymer chains.

When the sample is cooled below

T

trans

in the second step, the

molecular switches closes while the temporary shape that was

introduced in the earlier stage is retained (shape A in Fig. 8.7). The

third step reduces the applied stress, but the attained strain remains,

because of closed switches are blocked and elastically retained in

that state. The fourth stage brings the contraction and resumption

of the permanent shape of the specimen, with the temperature rise

above

T

trans

(shape B on a Fig. 8.7).

This short overview of shape memory materials should provide

a good introduction to the existing mechanism in the different types

of materials and its possible applications. It also brings a broader

vision of discussed behaviors and its similarities for the upcoming

section of this chapter.

8.3

Brief History of SMAs

Since the discovery of martensite in steels by Adolf Martens

around 120 years ago, scientists have wondered about the nature