Biomedical Engineering Reference

In-Depth Information

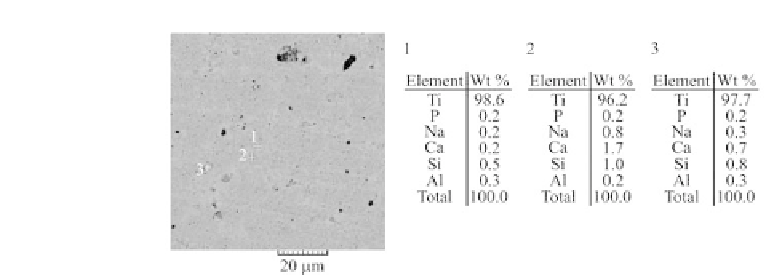

Figure 7.11

EDS spectra of surface of Ti-10 vol% 45S5 Bioglass mech-

anically alloyed for 20 h and heat treated at 1150˚C for

2 h [24].

As shown in Table 7.4 the Vickers microhardness of Ti-3 wt%

45S5 Bioglass and Ti-10 wt% 45S5 Bioglass nanocomposites are

500 HV and 620 HV, respectively and are higher than that of pure

microcrystalline titanium. The addition of silica to titanium has a

positive effect on the corrosion resistance of titanium. The corrosion

resistance increases with the rise of ceramic contents. The Ti-10 wt%

45S5 Bioglass nanocomposite possesses higher corrosion resistance

and thus higher corrosion current densities than microcrystalline

titanium.

7.5 Ti-Al

2

O

3

Nanocomposites

Alumina ceramics have good biocompatibility and good mechanical

properties (particularly the parameters of friction and wear). It is

biologically inert, which means that it practically does not emit any

components to the biological environment. Due to it high resistance

to wear by friction, this can signiicantly improve poor tribological

properties of titanium.

Amorphous material is form after 20 h of mechanical alloying

process [24]. The formation of the bulk nanocomposites was achieved

by annealing of the amorphous materials. XRD and EDS analysis of

Ti-10 vol% Al

2

O

3

showed the presence of α-Ti type structure with

nanograins of aluminum or aluminum oxide (Fig. 7.12). The average

crystallite size of heat treated Ti-Al

2

O

3

nanocomposites is about

35 nm.