Biomedical Engineering Reference

In-Depth Information

The formation of the bulk nanocomposites were achieved

by annealing of the amorphous materials in high purity gas at-

mosphere composed of 95% Ar and 5% H

2

at 1150°C for 2 h

(Fig. 7.8d). XRD analysis of Ti-10 vol% SiO

2

showed the presence of

α-Ti type structure with cell parameters

a

= 2.972 Å,

c

= 4.774 Å. The

formation of crystalline SiO

2

phase was not observed. According to

the Scherrer method of XRD proiles, the average size of heat treated

Ti-SiO

2

nanocomposites is about 40-50 nm.

EDS results indicate that the predominant phase in Ti-SiO

2

composites is titanium with content of silica or silicon particles.

The presence of some amount of iron atoms in the sintered

nanocomposites could be explained by Fe impurities trapped in the

MA powders from erosion of the milling media.

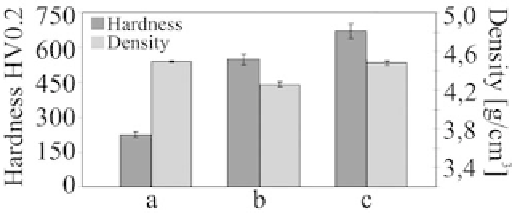

The Vickers microhardness of the sintered nanocomposites

exhibit various distribution corresponding to constitutional change

and increased with the rise of ceramic contents. The Vickers hard-

ness for Ti-3 vol% SiO

2

, and Ti-10 vol% SiO

2

nanocomposites

reaches 550 HV0.2 and 670 HV0.2, respectively, and are two times

higher than that of pure microcrystalline Ti metal (225 HV0.2);

see Fig. 7.10.

Figure 7.10

Vickers microhardness of studied nanocomposites; (a) Ti,

(b) Ti-3 vol% SiO

2

, (c) Ti-10 vol% SiO

2

[21].

Table 7.4 shows the polarization data obtained for sintered

composites and microcrystalline titanium, including corrosion

potentials (

E

C

), corrosion current densities (

i

C

), and corrosion

rate (

C

R

) values. According to Table 7.4, it is possible to observe

that ceramic doped to titanium had a positive effect on corrosion

resistance of Ti. Titanium composites with 10 vol% of silica have