Biomedical Engineering Reference

In-Depth Information

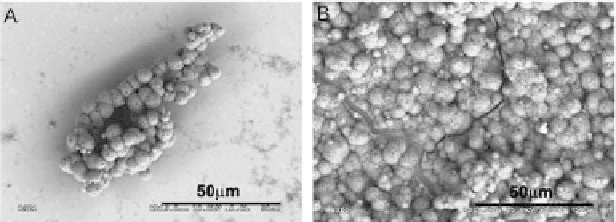

alloy, but unfortunately these implanted alloys underwent pitting

corrosion [26]. This pitting corrosion is attributed to the reduced

oxygen content at the interface between the passive layer and the

implanted layer [45, 46]. The implanted ions act as a barrier to

the diffusion of oxygen. The change of the corrosion resistance of

the calcium-implanted Ti-6Al-4V alloy after long-term exposure

into SBF is related with formation of calcium phosphates. The Ca-P

precipitations are more numerous after longer exposures (Fig. 5.32),

and the precipitated layer is continuous. The Ca/P ratio in the

precipitations on the implanted surface after the exposure for

720 h was about 1.66, which suggests hydroxyapatite formation.

Implantation of the calcium ions deinitely enhances the calcium-

phosphate precipitation.

Figure 5.32

Surface of the Ti-6Al-4V alloy implanted with a 1 × 10

17

Ca

+

/

cm

2

after exposure in SBF: (A) 168 h and (B) 720 h [26].

5.4

Corrosion of the Other Dental Materials

In medicine, the stainless steels which are typically used contain

17-20% Cr, 13-15% Ni, 2-3% Mo, and small amounts of other

elements. Cr is the element responsible for the high passivation

ability of these alloys. An increase in Cr and Mo content leads to

an increase in the resistance against localized corrosion. Although

the main problem is related with Ni, it is commonly added as

the austenite forming element, but unfortunately, highly toxic

for the human. The other Co-Cr-type alloys have high corrosion

resistance [53]. The Co-Cr alloys are superior to stainless steel, both

in fatigue and wear resistance. In all Cr-containing alloys, Cr

2

O

3

forms on the surface acting as a corrosion protective layer.

Taher and Al Jabab [50] investigated the galvanic corrosion

behavior of a different commercial dental alloys (Table 5.11) coupled