Biomedical Engineering Reference

In-Depth Information

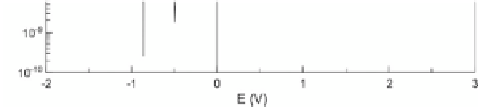

Ti, which is extremely important in biomaterials applications. The

porous TiO

x

has wide passive range (plateau on the polarization

curve). This passive range suggests that the surface oxides are

stable and no pitting occurs. The current density value in the

passive range is almost the same in both cases. For pure Ti at higher

positive potentials, a transpassivation and transformation of oxide

into soluble salt is observed, which results in fast metal dissolution

(a). This behavior was not observed for the porous TiO

x

(b) and the

surface layer protect material against dissolution.

Figure 5.22

Potentiodynamic corrosion curves for pure Ti (a) and porous

TiO

x

layer (b) in Ringer's electrolyte [14].

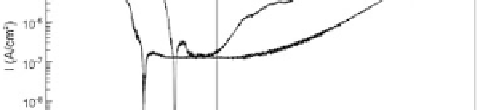

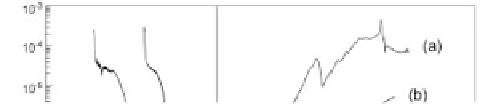

The Ti-glass or Ti-HA bionanocomposites are a new class of

biomaterials, with interesting mechanical and biomedical properties,

prepared by Niespodziana

et al

. [33, 34]. The corrosion properties of

the Ti-glass (45S5-Bioglass) were potentiodynamically investigated

in Ringer's solution by Jakubowicz

et al

. [16] (Fig. 5.23). After

electrochemical etching, the surface of Ti-glass nanocomposites has

a slightly better corrosion resistance (b) than the parent not etched

sample (a). The corrosion current density, estimated from the Tafel

extrapolation, of the nanocomposite before and after electrochemical

treatment is 5.1 × 10

-6

A/cm

2

and 1.87 × 10

-6

A/cm

2

, respectively.

The lower corrosion current density indicates better corrosion

resistance and lower corrosion rate. The surface after etching is

covered by thicker oxide, than samples not etched with native oxide.

These anodic oxides provide better corrosion resistance of the

electrochemically treated Ti-45S5 bionanocomposites [16].