Biomedical Engineering Reference

In-Depth Information

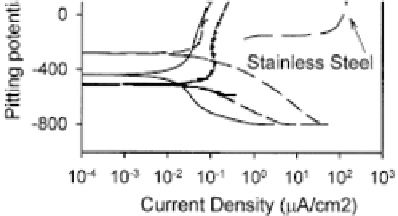

of 0.30 for bare Ni-Ti [47]. Rondelli and Vicentini [38] investigated

the Ni-Ti dental wires in artiicial saliva (Fig. 5.11). The Ni-Ti alloy

has a wide passive range that extends up to very high potentials, and

absence of hysteresis loop, which indicate high resistance to pitting

corrosion. For comparison, for the cobalt alloy no pitting occurs at

very high potential, whereas the stainless steel exhibited pitting of

about 400 mV versus SCE (Fig. 5.11). The Ti-Ni alloys have suficient

resistance against pitting corrosion, comparable to the cobalt-based

alloy, and much higher than the stainless steel wire [38].

Figure 5.11

Potentiodynamic tests of orthodontic wires in artiicial saliva

at 40

°C

[38].

Preparation of Ti-alloys with highly cathodic elements, such as

Ag, Pt, and Pd could improve corrosion resistance of the implant

alloys. Shim

et al

. [48] and Zhang

et al

. [57] reported that Ti-Ag

alloys have better corrosion resistance than that of pure titanium

and they predicted that Ti-Ag alloys are less sensitive to luoride

ions, which is extremely important in dental implant applications.

Zhang

et al

. [57] investigated the corrosion behavior of the Ti-Ag

alloys in artiicial saliva with luoride ions. Figure 5.12 shows the

potentiodynamic polarization curves of the commercially pure

Ti (CP Ti) and the Ti-Ag alloys in the artiicial saliva solutions. In

the luoride-free solution (Fig. 5.12a), both CP Ti and the Ti-Ag

alloys show passivation behavior without obvious active-passive

transition. The passivation and corrosion current density are lower