Biomedical Engineering Reference

In-Depth Information

effects as well as a quantitative correlations between them and topographical non-

identity of fabrics, roughness and dynamic wetting results [17, 18], were analysed

in respect of liquid transport driven into a porous system by capillary forces. In

general, wetting of a fibrous assembly, such as a fabric, is a complex process. Par-

ticularly, capillary flow is not determined by a constant advancing contact angle,

as frequently assumed [11], but it depends on a dynamic contact angle correspond-

ing to the instantaneous velocity of the moving meniscus. In our studies was found

that measured dynamic contact angle of water, as a consequence of wetting, is less

expressive in respect to changes in the topographic structure of textile surfaces.

Moreover, wicking occurring within the spaces between fibres, being previously

wetted, strongly controls the fabrics cleanability.

As most textile processes, including their detergency, are time-limited, the rate

and direction of wicking is therefore important. It is known that the wicking rate is

not solely governed by interfacial tensions and the fibres wettability but it is also

depends on capillary substrate dimensions and the liquid viscosity [11, 19].

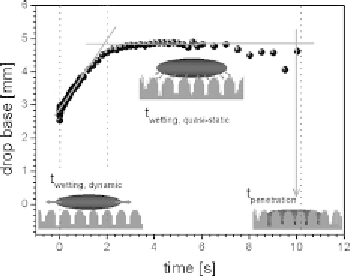

On the basis of macroscopic water drop base changes, the wetting behaviour

of the water drop can be divided into three different regimes (Fig. 9): dynamic

wetting, defined as growing of the drop diameter depending on time (also know

as spreading), quasi-static wetting, here the drop diameter remains approximately

constant and penetration, which is marked by liquid drop absorption into fabrics

depending on time.

As periodic surfaces, all textile materials show horizontal and vertical repeti-

tive unities. For this reason, different length scales have to be taken into account

by interpreting topographic data measured [14]. The topographical study of textile

materials using scales permits to characterize surfaces considering their specific

morphologies due to the type of weave, yarn and filament/fibres separately. The

use of a scales concept to characterize textile surfaces aims to be a new skill to

correlate textile parameters, topography and topographical changes with interface

Figure 9.

Three different wetting regimes on a textile surface. Reprinted from

Textile Research Journal

80, Calvimontes A., Dutschk V., Stamm M., pp. 1004-1015, Copyright (2010)

, with permission from

SAGE publications.

Search WWH ::

Custom Search